The world of industrial manufacturing is quickly evolving with the emergence of cutting-edge technology such as laser cutting. Laser cutting provides a more efficient, cost-effective, and accurate method of industrial manufacturing than ever before. With the introduction of laser cutting technology, the future of industrial manufacturing is poised to take a massive leap into the future. Join us as we explore the incredible opportunities that laser cutting jobs can provide to the industrial manufacturing sector.

How Laser Cutting is Being Incorporated into Industrial Manufacturing

What Industries are Utilizing Laser Cutting?

technology is becoming increasingly popular in a variety of industries. The automotive industry, electronics production, medical device manufacturing, industrial tooling, and sheet metal fabrication are just a few of the industries using laser cutting. Automotive companies have used the technology to cut vehicle parts quickly and accurately, allowing for a faster production line.

The medical device industry is able to cut tools and implants precisely and to exact specifications with laser cutting technology. Electronics manufacturers are able to make intricate components quickly and without the waste of material or labor that comes with manual cutting methods. Tool and die companies are now able to produce more intricate and accurate parts for industrial machines using laser cutting technology.

Benefits Industrial Manufacturing Facilities Enjoy Through Laser Cutting

is rapidly becoming a necessary, modern tool for industrial manufacturing facilitiess. Laser cutting has been around since the 1960s, but recent technological advances in software, materials, and cutting processes has made it increasingly popular, creating a wide range of opportunities and benefits to industrial manufacturing companies. One of the primary benefits of using laser cutting for industrial manufacturing is improved quality of the manufactured products.

Future of Industrial Manufacturing with Laser Cutting Jobs

Growing Demand for Laser Cutters

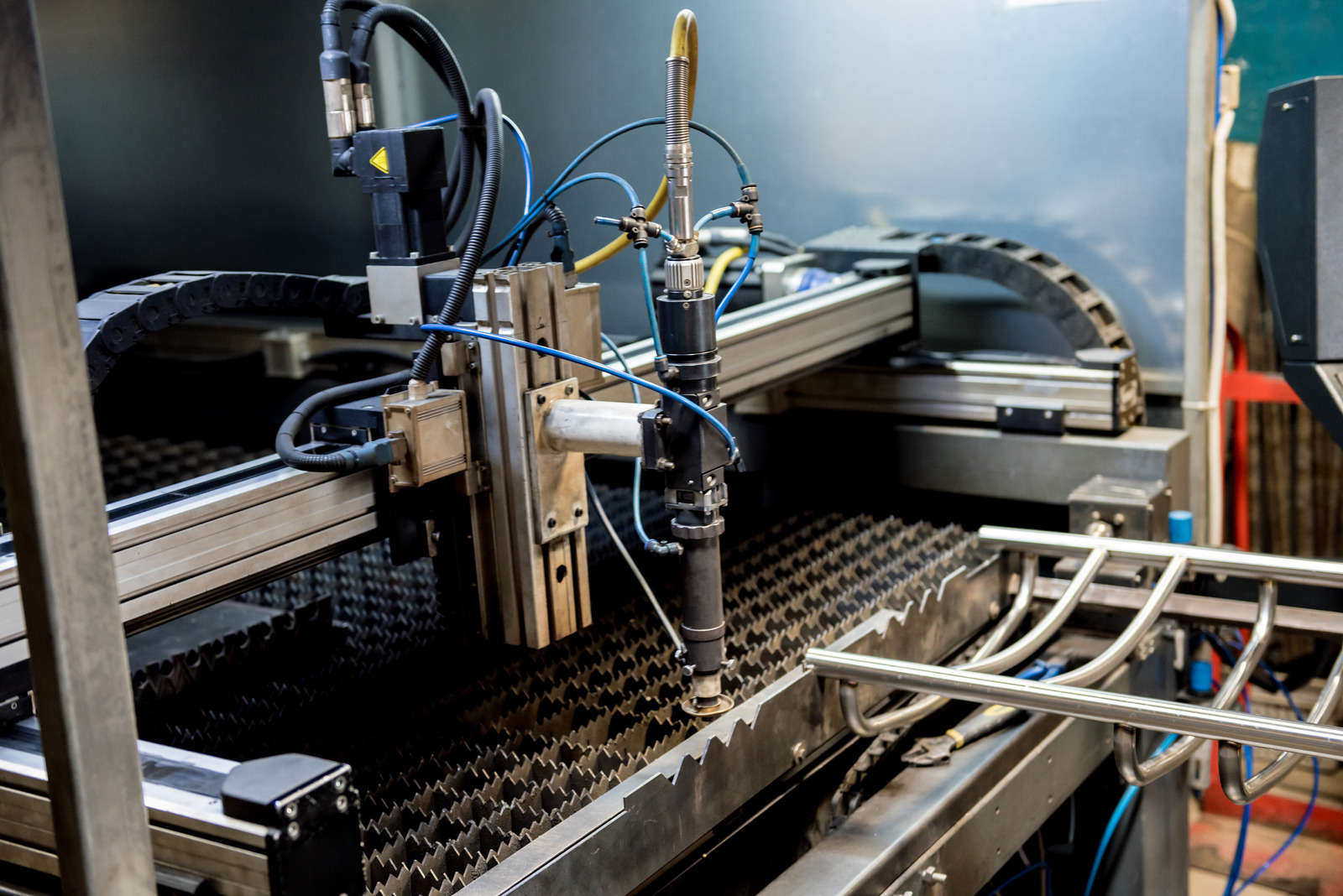

is an industrial process used to cut and shape metal and other materials , by focusing a high-powered laser beam precisely on the material. Laser cutters have been around for some time, but their uses have grown significantly in recent years, as the technology has evolved and become ever more powerful. The increasing demand for laser cutters is largely a result of the cost savings, precision and speed with which they can cut and shape materials, as well as their ability to accurately handle complex shapes and materials that would otherwise be too thin, brittle, or otherwise difficult to handle with traditional methods.

Automation and Software Integrations

often relies heavily on automation and software integrations in order to ensure that production runs are done quickly and efficiently. Automation helps reduce waste, ensure consistent quality, and speed up production time. Software integration is also important as it allows for more precise and intricate designs to be produced and eliminates the need for manual work.

Automation and software integration also provide a more secure platform in terms of data storage, making it easier to track and monitor production runs.

Skilled Labor Shortage for Laser Cutters

is an important process for many industrial manufacturers today. As businesses look for ways to speed up their production process and remain competitive in their respective industries, laser cutting has become increasingly popular. The problem, however, is that finding skilled labor for laser cutting jobs is becoming increasingly difficult.

As the demand for laser cutting services in the industrial manufacturing sector grows, companies are scrambling to find enough skilled laser cutters to meet their needs.

What engineering sector makes the most use of laser cutting?

technology is an essential tool for industrial manufacturing, and many of the major engineering sectors are taking advantage of it. In particular, the automotive, aerospace, electronics, and medical industries are using laser cutting to make intricate parts and components. This technology facilitates faster, more precise cutting than traditional machining.

By using lasers, manufacturers can reduce production time, minimize waste, and make parts that are much more exact and consistent than those produced with older cutting techniques. Laser cutting provides tremendous benefits for the automotive industry. For example, the technology allows for custom-crafted vehicle components like spoilers, grilles, and fenders.

It also helps produce fuel system parts with greater precision and accuracy.

What type of manufacturing is laser cutting?

is a highly precise and advanced form of industrial manufacturing. In laser cutting, a laser is used to cut and shape materials such as metals, plastics, ceramics, and other similar materials. The laser cutter, typically a CO2 laser, is used to precisely direct the laser’s beam to follow a specific path and create precise cuts and shapes in the material.

Conclusion

Benefits of Utilizing Laser Cutters in Industrial Manufacturing

jobs have revolutionized the way industrial manufacturing is done. By using laser cutting, industrial manufacturers can make precise cuts with extremely high accuracy and precision. This means that workers can make parts and products with greater accuracy and speed than they could with traditional cutting methods.

Additionally, laser cutting jobs require less energy to produce the same results as a traditional cutting approach, meaning that companies can save money on energy costs and labor costs. The use of laser cutters in industrial manufacturing offers many other benefits as well, such as a much smaller environmental footprint.

The Bright Future of Laser Cutting Jobs in Industrial Manufacturing

jobs are rapidly revolutionizing industrial manufacturing. This cutting-edge, innovative technology has allowed for higher-spec parts to be produced in shorter amounts of time. Laser cutting is incredibly accurate and precise, making it ideal for creating intricate designs and complicated parts faster and better than traditional machining.

As the industrial manufacturing industry continues to grow, laser cutting jobs are setting a new standard for the production process. In addition to its speed and accuracy, laser cutting also allows for a safer working environment by eliminating potential contact with moving parts and hazardous materials. By employing laser cutting as an integral part of their process, industrial manufacturers have increased their ability to protect their employees while still managing to maintain outstanding production rates.

Resources to Learn More About Laser Cutting and Its Uses in Industrial Manufacturing

is a type of material processing that uses a highly focused, high-powered laser beam to melt and cut a variety of materials. In industrial manufacturing, it is often used to create intricate, precise cuts in sheets of metal, plastics, or other materials. It can also be used to cut out shapes from larger pieces, like electronic components or intricate designs.

For those curious to explore this process further, there are several resources available.