As a company, it is important to have the best possible resources and services at your disposal. Partnering with a laser cutting company can give you a clear advantage over the competition. Laser cutting services provide superior precision and a wide range of capabilities to meet all your needs. Here, we will discuss the benefits of partnering with a laser cutting company, from advanced technology to cost savings.

The Cost Benefits of Laser Cutting

Low cost of materials

One of the main advantages of partnering with a laser cutting company is the cost savings associated with it. Laser cutting materials, such as metals and plastics, are very cost-effective compared to traditional cutting methods. Laser cutting provides a level of accuracy and detail that cannot be achieved with traditional methods.

This means that you can use less material and still achieve excellent results. Additionally, laser machines require significantly less energy than other cutting methods, which can also drastically reduce costs. Another advantage of laser cutting is the speed with which it can cut materials.

Minimized manual labor

One of the major advantages of partnering with a laser cutting company is the minimized manual labor involved. From quickly cutting complex shapes to automatically producing intricate parts, laser cutters can revolutionize production processes by reducing the amount of labour required to complete any particular task.

Increased efficiency in production

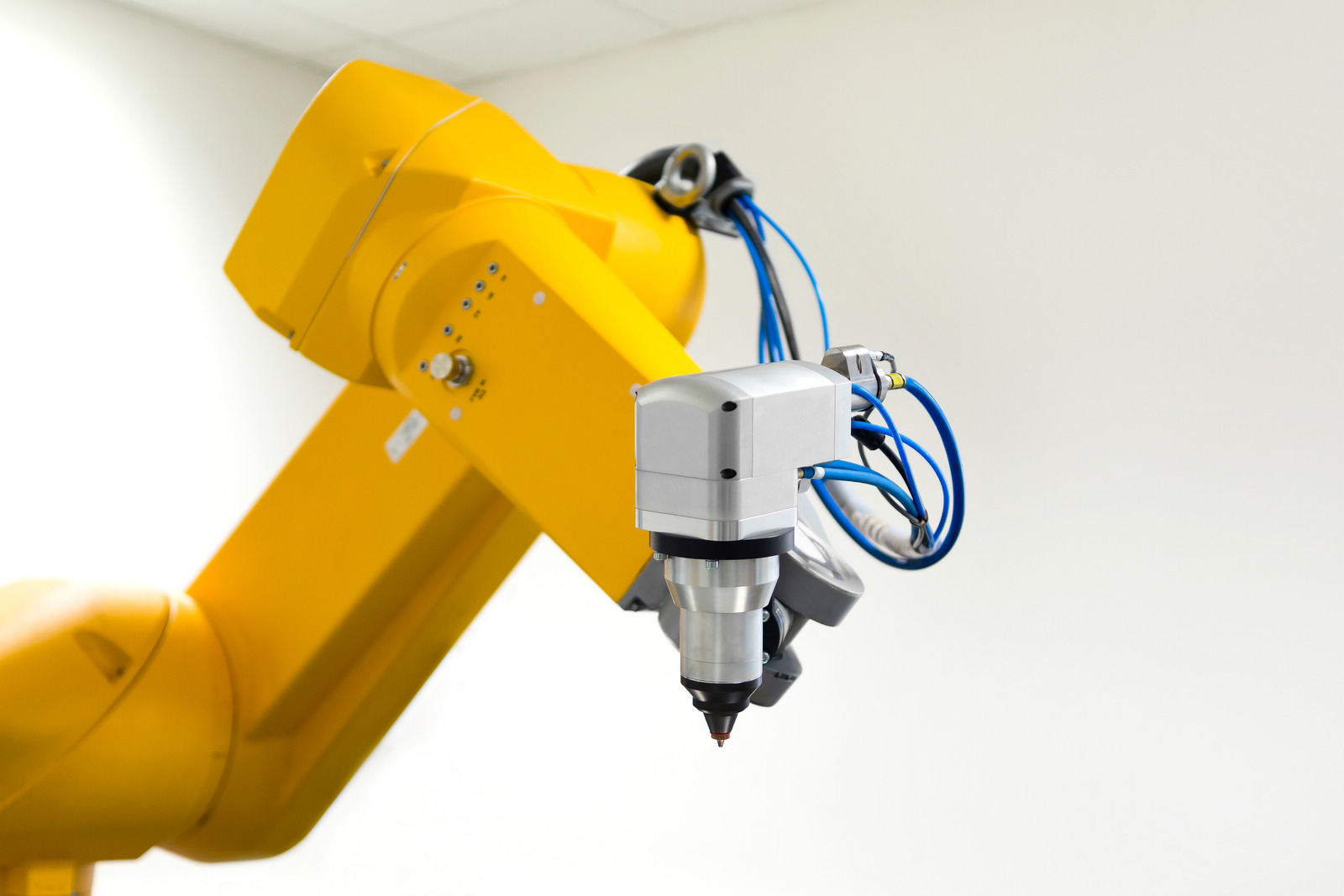

Partnering with a laser cutting company can offer increased efficiency in production, making it a great investment for any business or individual looking to reduce manufacturing costs and produce quality products. By using a laser cutting machine, businesses are able to produce efficient shapes and intricate designs faster than ever before. Laser cutting uses a high-powered laser to cut through materials like wood, steel, glass, and more, with precision and accuracy.

Reduced turnaround time

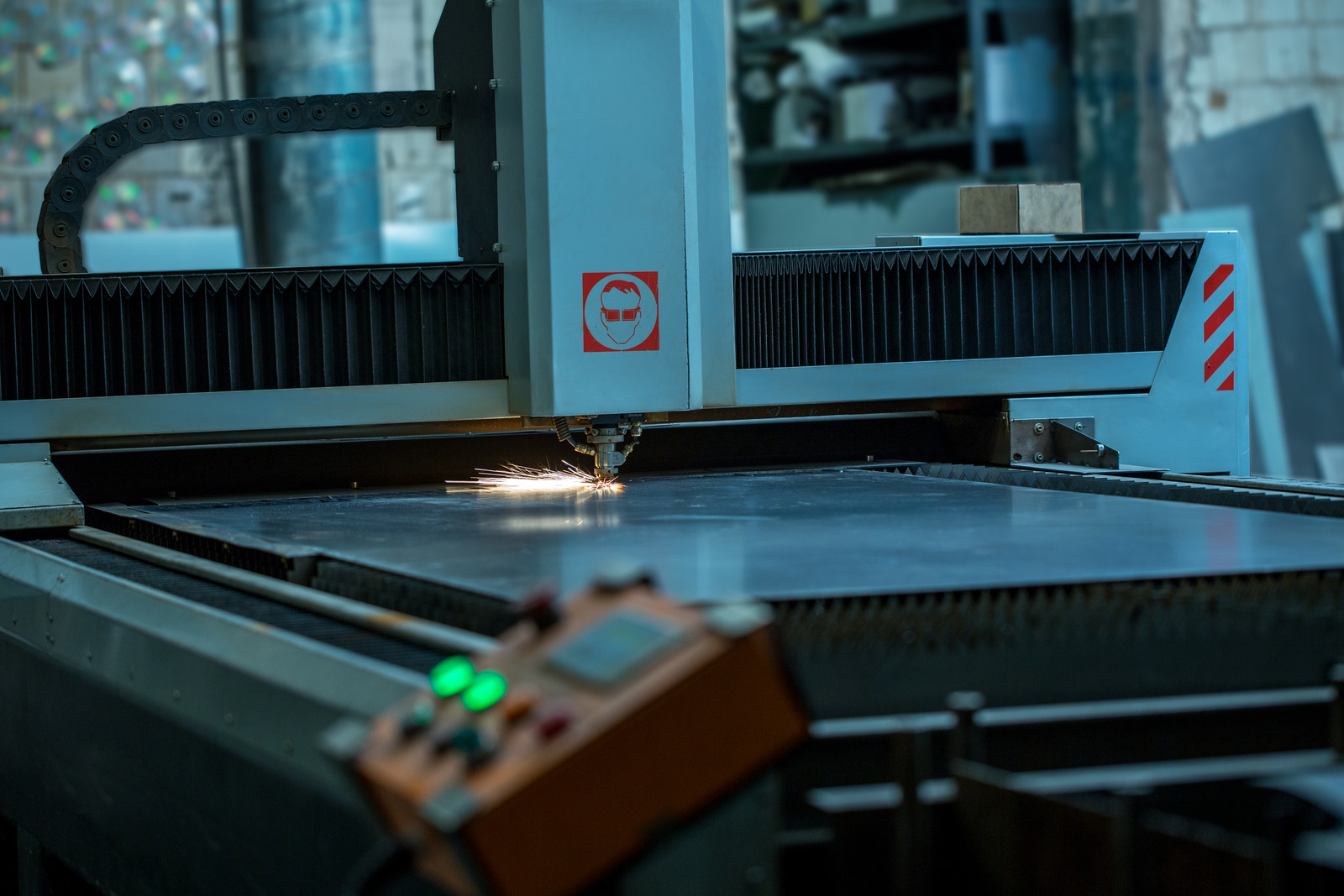

One of the key advantages of partnering with a laser cutting company is the reduced turnaround time they can offer compared to traditional methods. Lasers can cut and engrave much faster than traditional methods such as machining, which is why they’re quickly becoming the go-to choice in production and manufacturing. With a laser cutter, you can quickly get the materials cut to size and the parts ready for assembly.

This can significantly reduce the total turnaround time and help your project be completed faster. Additionally, the precision that a laser cutter can offer is second to none.

The Accuracy Benefits of Laser Cutting

Ability to produce complex shapes and intricate details

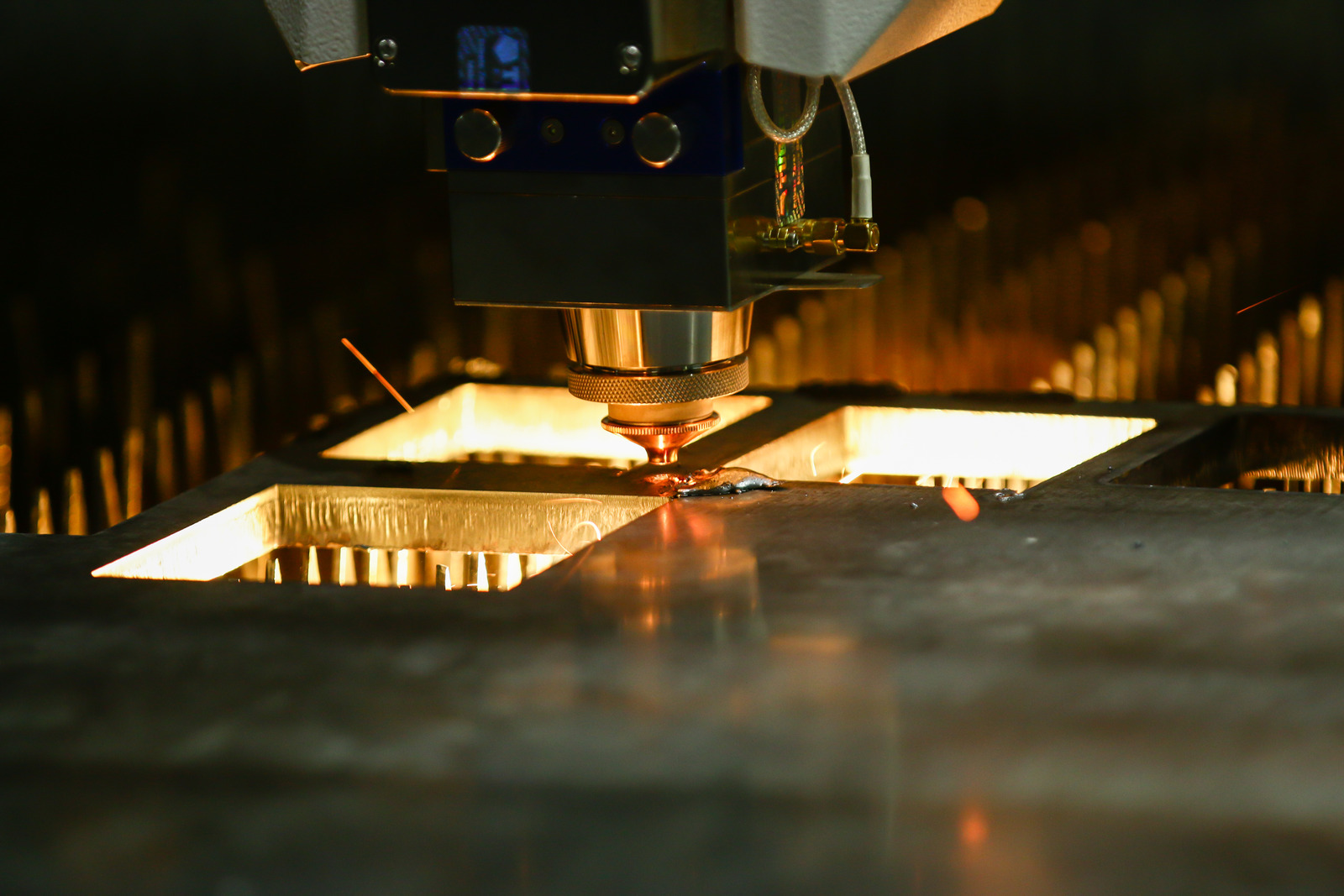

Laser cutting is an incredibly precise method of cutting materials. With the ability to produce complex shapes and intricate details, partnering with a laser cutting company can provide a lot of advantages. One of the main advantages of laser cutting is its accuracy.

In comparison to traditional methods of cutting, laser cutting lets you produce very precise and intricate cuts with an incredibly high level of accuracy. This accuracy can be incredibly beneficial in many cases. For example, if you’re carrying out intricate decorative cutting, laser cutting can ensure each and every shape you produce is exactly the same.

High degree of precision and accuracy

When it comes to cutting intricate, detailed shapes and objects, choosing to partner with a laser cutting company can provide a high degree of precision and accuracy. By using cutting-edge laser cutting technology, a laser cutter can help you to achieve very precise measurements and tolerances. This makes laser cutting ideal for a range of complex parts, components, and other products that require precision.

The Safety Benefits of Laser Cutting

Reduced exposure to hazardous materials

One of the main advantages of partnering with a laser cutting company is the reduced exposure to hazardous materials. Thanks to the precision of laser cutting, the hazardous material exposure is greatly reduced when compared to traditional cutting methods. This means that it is safer for the workers and for the environment.

Laser cutting eliminates the use of drill bits, saws, and other traditional cutting tools that involve metal chips, sparks, and grinding dust from contact with a cutting object. Instead, these are replaced by a single laser beam, allowing for a clean, efficient cut.

Fewer risks associated with manual labor

The advantages of partnering with a laser cutting company are numerous, particularly when it comes to the safety benefits it brings. One of the most significant of these is the reduction of risks associated with manual labor, which can be especially dangerous in certain industries. The use of a laser cutter eliminates the need for workers to be placed in direct contact with dangerous materials, as the cutting is done remotely.

This eliminates the chances of injuries and accidents occurring during the process, providing a much safer working environment for everyone involved.

The Environmental Benefits of Laser Cutting

Reduced greenhouse gas emissions

Partnering with a laser cutting company is a great option for businesses looking to benefit from reduced greenhouse gas emissions. Laser cutting offers a range of advantages compared to other cutting methods, making it a great choice for businesses looking to reduce their environmental impact. One benefit of laser cutting is that it requires no direct physical contact with the material.

This eliminates the need for lubricants and helps to reduce the emissions associated with them. Additionally, laser cutting emits less dust and smoke, resulting in much cleaner operation. Laser cutting is also far more efficient than other methods, allowing businesses to reduce their energy consumption.

This can help to significantly reduce the amount of greenhouse gases emitted during the cutting process.

Reduced energy consumption

One of the key advantages of partnering with a laser cutting company is that it can drastically reduce energy consumption. Laser cutting technology is much more efficient than traditional cutting methods like sawing, milling, or punching. With laser cutting, electrical energy is converted directly into laser energy, allowing for extremely precise and accurate cuts every time.

This means minimal wastage of energy and material, thus resulting in much lower consumption of energy overall.

Is a laser business profitable?

One of the advantages of partnering with a laser cutting company is that their services can be highly profitable. With the help of a laser cutter, businesses can create intricate designs and precision cuts with a fast turn-around time. This can boost growth and profits for any level of operation.

For example, a small shop could easily update their entire product line with high-end fixtures and parts in a fraction of the time and cost it would take with traditional methods.

Conclusion

Summary of the benefits of working with a laser cutting company

In conclusion, partnering with a laser cutting company offers numerous benefits. For starters, laser cutting is a precision process, with your materials cut to exact specifications with a high degree of accuracy. Laser cutting also allows for faster production times, meaning that projects can be completed much more quickly, cutting down on overall production costs.

The superior surface finish of laser cut parts also allows for enhanced aesthetics and expedited post-cutting treatments such as painting and plating.

Acknowledgement of the importance of choosing the right laser cutting partner

When it comes to choosing the right laser cutting partner, it’s important to take into consideration all of the advantages they can provide. A laser cutter is a specialized tool that can be used to cut, engrave, and mark materials quickly, smoothly, and accurately. It has become a core technology for many fabrication and laser engraving projects meaning it’s incredibly useful in a wide variety of applications.

While it has its advantages, it is important to choose the right laser cutting partner in order to maximize its potential. Working with an experienced laser cutting partner can provide several distinct advantages that can benefit your project. When compared to a standard cutting tool like a saw, a laser cutter is much faster and more precise.