Having the right tools, technology and knowledge are essential components of any successful business. Introducing Laser Cutting CNC as a tool to your business is an important step if you’re looking to take your business to the next level. Lasers are a tool for precision material processing with highly repeatable results. They are capable of quickly and accurately cutting and engraving complex shapes. Laser Cutting CNC is a powerful, reliable, and efficient tool that give businesses the potential to maximize production and enable creativity. In this document, we will discuss the benefits of incorporating Laser Cutting CNC into your business.

Laser Cutting CNC Technology

What is a CNC Machine?

CNC technology A CNC machine – or Computer Numerical Control machine – is an automated device used for the precise cutting, shaping, or machining of a variety of materials such as metals, stone, glass, plastics, and wood. Generally thought of as industrial machinery, CNC machines are becoming increasingly accessible to businesses with smaller budgets. CNC machines use software programs to accurately control the movement of cutting tools, such as drills, grinders and routers, held in place on a spindled arm.

This allows for the precise creation of complex shapes, curves, and designs in a variety of materials.

How Does Laser Cutting Work?

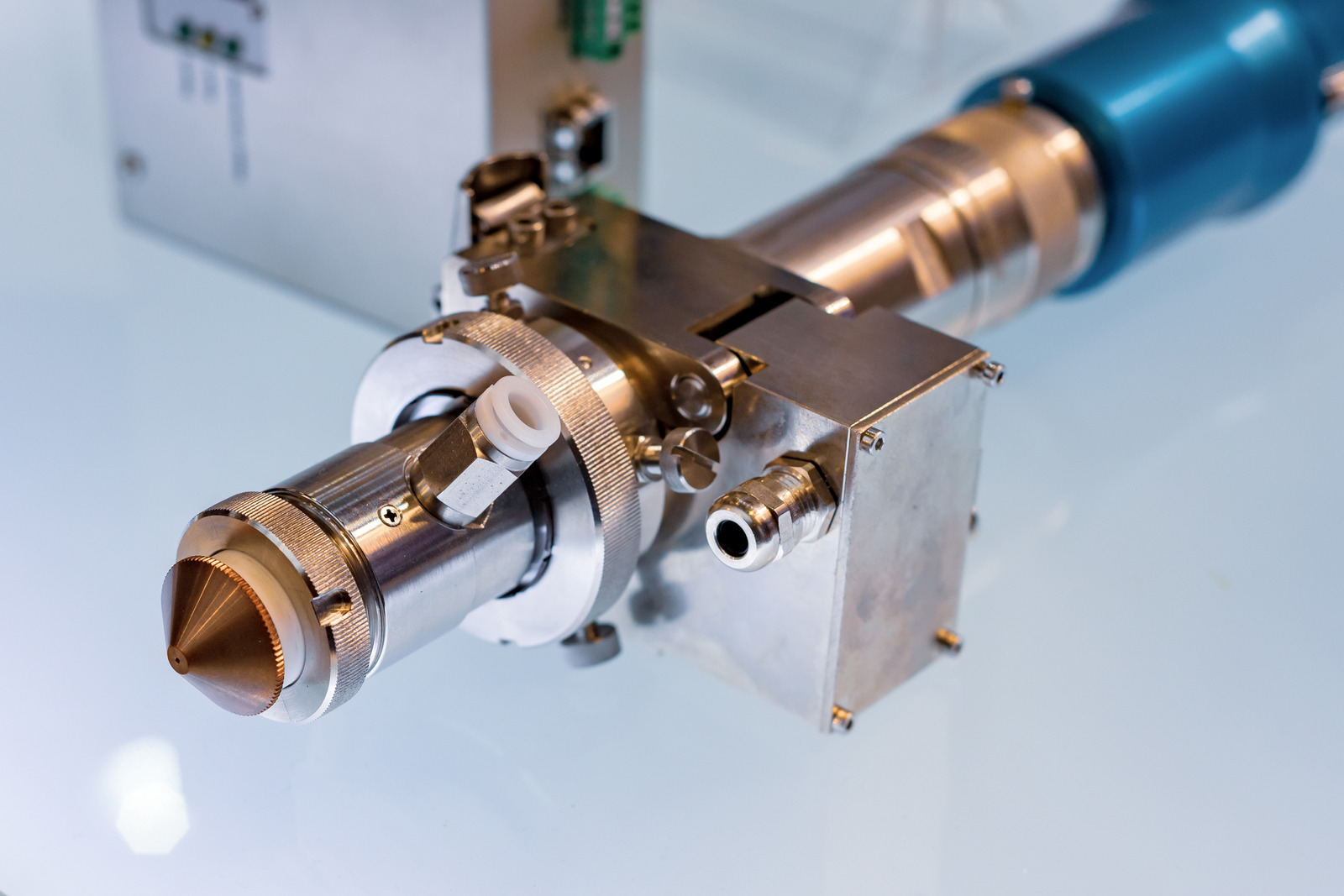

Laser cutting is a process of using a high-power laser beam to cut and shape materials, such as metal and plastic. A laser cutting machine consists of a laser beam source, a laser optics system and precision X-Y axes from a CNC (Computer Numerical Control) system. The entire process takes place at incredible speeds.

First, the laser beam gets passed through the laser optics system where the beam is adjusted for intensity, focus, and size. Then, the beam is directed right to the X-Y axes of the CNC which directs the beam onto the material surface.

Equipment Needed

What is Needed for Laser Cutting CNC?

software If you’re looking to start using laser cutting CNC (computer numerical control) in your business, there are a few items you’ll need to get started. The most important of these items is the laser cutting machine itself. A laser cutting machine is a piece of industrial machinery that uses a laser beam to cut, engrave, and mark materials like metals and plastics.

The machine will come with a computer terminal that allows you to input instructions into the machine and control it. Once you have a laser cutting machine, you’ll need to purchase laser cutting software. Laser cutting software is used to generate and control programs that send instructions to the laser cutter’s computer terminal.

Cost Estimation

cnc equipment Cost estimation is a key factor to consider when introducing a new laser cutting CNC machine to your business. The cost of a laser cutting machine can vary widely, but you can easily calculate the estimated cost of a laser cutter by taking into account the following factors: size of the machine, type of laser, required power, and additional tools and materials needed.

Setting up Laser Cutting CNC

Steps for Setting Up

CNC Setting up a laser cutting CNC machine is an exciting process and one that can bring a lot of value to your business. There are several steps involved in the process to get your machine up and running. First, you’ll need to decide where to put your machine and how much space you’ll need.

Laser cutting CNC machines are fairly large, so make sure you have enough room to accommodate it.

Tips for Ensuring Smooth Operation

CNC When introducing laser cutting CNC to your business, planning ahead and taking the time to properly set up your machine and plan out your workflow is key to ensuring smooth operation. Here are a few tips to help you get started. First, choose the right laser cutting machine for your business.

Think about the materials you’ll be cutting, your production volume, and other factors to determine the machine that will best meet your needs. Do some research on models and manufacturers, read reviews, and talk to other businesses with experience in the field. Second, make sure to have the right safety protocols in place when you set up your machine.

Considerations for Laser Cutting CNC

Space Requirements

CNC When it comes to introducing laser cutting CNC to your business, one of the big considerations is space requirements. A laser cutting machine is not a small machine and comes with several components beyond just the laser cutter itself. In addition to the space for the cutter, there will be other machines for moving and loading parts, a set of wheels to move the material, and various other components such as electrical panels and hoses.

Ideally, you want the work area to be clear and free of clutter and debris so that you can easily move parts and feed them into the cutter.

Safety Precautions

CNC When introducing a laser cutting machine or laser cutting CNC to your business, safety should be a primary concern. Laser cutting machines and CNCs use high powered laser beams to precisely cut and engrave materials, and as such you need to ensure adequate safety measures are in place to protect your workers and equipment.

Is laser cutting the same as CNC?

No, laser cutting and CNC (Computer Numerical Control) are not the same. CNC is a form of machining that uses computer-controlled machines to perform predetermined instructions. On the other hand, laser cutting is a process used to precisely cut and engrave a variety of materials using a focused beam of light.

How can I make money with a laser cutter?

If you invest in a laser cutting machine, you have the potential to turn a profit with it. Laser cutting is the process of using a focused beam of light to cut through materials such as wood, plastic, and metal to create a pattern. This technology is gaining popularity because it is a fast, precise, and cost-effective way to create parts and products.

Conclusion

Summary of Benefits

CNC In summary, introducing laser cutting CNC to your business is a great business decision that can help your company save time, money, and energy while creating superior products. With its high precision, speed, and flexibility, laser cutting CNC can help you create complex and intricate designs that cannot be achieved with traditional cutting methods.

Overall Value of Laser Cutting CNC to Your Business

machine & CNC technology Introducing laser cutting CNC to your business can provide a range of benefits. Laser cutters offer a variety of advantages over other traditional tools, making them a great addition to any workshop or manufacturing facility. The unique properties of a laser cutting machine & CNC technology allows for greater accuracy and repeatability, as well as faster production speeds.

This speed of production provides a significant cost savings over other methods, as the time-saving translates into money saved. Additionally, laser cutting CNC machines provide a higher level of accuracy, allowing for better product consistency and quality assurance. Laser cutters also require less setup and preparation, saving time and money.