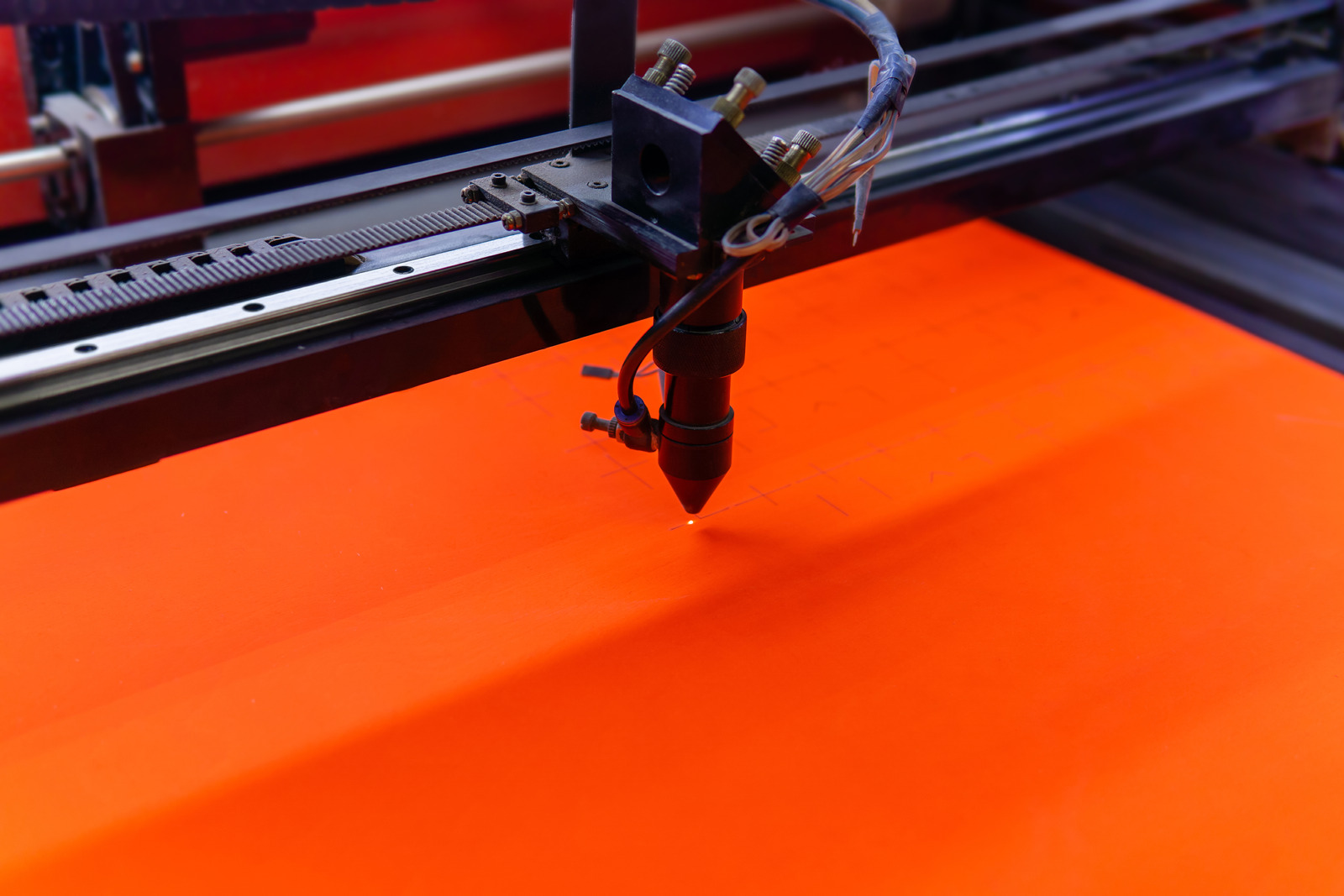

When it comes to laser cutting, material waste, process disruption, and runaway jobs can all lead to a frustrating situation. But with the proper knowledge and tools, most of the issues associated with laser cutting can be avoided or quickly corrected. In this article, we will explain the most common laser cutting troubleshooting problems and provide some tips on how to handle them when they arise.

Essential Laser Cutting Safety Procedures

Protective Eyewear

Protective eyewear is an essential safety precaution when laser cutting. The invisible, concentrated beam of laser light can be hazardous to your vision, so it’s important to make sure your face and eyes are fully protected when operating a laser cutter. There are several types of eyewear that you can use to protect yourself.

Laser safety glasses are specifically designed to filter out the wavelength of the laser cutting system, so they are the most protective option. Goggles or helmets can also be used for extra protection.

Proper Ventilation

When it comes to laser cutting, proper ventilation is essential for both safety and quality outcomes. While laser cutting produces fumes that need to be reliably extracted, also adequate oxygen levels within the laser cutters themselves are necessary for an optimal performance. Without proper ventilation, the machine could overheat, leading to a poor quality cut, or even to fire and smoke, which can cause a great deal of damage.

For this reason, it is incredibly important to make sure you have the right kind of ventilation in the area surrounding the laser cutting tool.

Material Safety

Working with lasers can be a dangerous job, and it pays to take the necessary precautions when operating a laser cutter. Material safety is key for both the operator and those around, so it’s important to make sure all safety procedures are followed. To start, make sure you’re using appropriate materials for laser cutting.

Different materials absorb laser light differently, meaning some items could crack or splinter when exposed. Check if the material is fume-sensitive or combustible as well, as lasers can create toxic fumes when used with certain materials.

Troubleshooting Methods

Checking the Setup

When laser cutting, it is important to assess any issues that occur and take the necessary action to fix them or prevent them from occurring in the future. Common issues and troubleshooting methods include checking the setup alignment, inspecting the material for scratches, maintaining the cutting head properly, ensuring the material is evenly placed, and ensuring the power settings are correct.

- Check the alignment of your laser head and the material you are cutting. Make sure everything is straight and parallel to create a consistent quality cut.

- Inspect the alignment of your mirrors and lenses. This can affect the quality of the cut as well as its accuracy.

- Make sure your material is properly secured. If the material moves during cutting, the results can be unpredictable and inaccurate.

- Ensure your material is compatible with the laser used. Different lasers have different cutting capabilities, so the choice of material is important.

- Make sure you are using the proper settings. Too much power can cause an overcut and too little can cause a burnt finish or not cut all the way through.

Laser Head Alignment

Having the proper laser head alignment is an essential part of getting a clean and accurate cut when it comes to laser cutting. However, sometimes things can go wrong, such as warping of the cut or uneven edges. If you’re having issues with your laser cutting head alignment, a few things can be done to troubleshoot and fix it.

The first thing to check is to make sure the material you’re cutting is properly laid out on the cutting bed. If it’s not, it can result in inaccurate cuts.

Laser Focusing

When it comes to laser cutting, focusing is a key element in producing a quality result. If you’re having trouble with your laser cutting and your results aren’t quite right, one of the first things that should be checked is the laser focusing. If the laser isn’t focused properly, it can result in poor cutting results, or even no results at all.

You can check the focusing of a laser-cutting machine by doing a few simple tests. First, you can move the cutting head around to see if the cutting beam is focused at the same point.

Interfacing with the Software

Interfacing with the software is a crucial part when laser cutting and troubleshooting. It is important to know how to correctly use the different types of software and hardware to interface with your laser cutter. When things go wrong, there are a few basic troubleshooting methods to identify the root cause of the problem.

First, you should check to see if there is an error message displayed on the machine’s monitor.

Checking the Material

Warping

When laser cutting, warping can sometimes be a problem that crops up. Warping occurs when the material during laser cutting curls up or bends in a certain direction. It’s often caused by the material not being stacked correctly before it is cut or not being adequately secured during the process.

The first step to troubleshoot warping is to check the material itself. Make sure the material is properly stacked before cutting the first sheet and that all sheets remain in place during the cutting process.

Residue

When it comes to troubleshooting laser cutting, one of the most common issues that can pop up is residue. Residue can be caused by a variety of factors, and it’s important to check for it regularly regardless of the material being used for cutting. The most common cause of residue is if the laser is not powerful enough to fully penetrate the material in one pass.

This results in material that is left behind and can usually be spotted by a black discolouration. If this is the case, one of the best ways to rectify this is to ensure the laser power is turned up high enough to penetrate the material through in one go.

Smudges

When it comes to laser cutting, smudges can be a difficult issue to tackle. Smudges occur when the laser beam interacts with the material in an unintended way, often leaving behind unwanted marks. When this happens, there are few tips you can do to try to correct the issue.

First, you should check your material to make sure it is clean and free of debris. If any debris is present, then it may cause the laser to burn it instead of cutting the material, resulting in a smudge.

Knowing When to Contact a Professional

Types of Maintenance Needed

Whether your laser cutting machine is functioning at a professional level for a business, or for personal use at home, some basic maintenance can be done to keep it in working order. These types of maintenance can do wonders in preventing or correcting a wide variety of problems that may arise. The most simple of these is simply to take a moment and make sure you have all the necessary components in order and that connections are securely in place.

If one of the wires or plugs appears to be loose, it is important to tighten or reattach them as soon as possible.

Knowing When to Make Repairs

When it comes to laser cutting troubleshooting, knowing when to make repairs can be tricky. Figuring out if your machine is functioning properly can be difficult if you don’t have experience working with laser cutters. However, if you can do some basic troubleshooting, you may be able to determine if you need the help of a professional.

First, you need to identify the problem. Check the settings on the machine and see if anything is off.

Why is my laser not cutting through?

When it comes to laser cutting, sometimes things can go wrong and you might find that your laser isn’t cutting through your material. Before troubleshooting, it is important to identify the materials you are working with, and make sure to use the right settings for that specific material. Your laser cutter should come with a guide on what settings to use depending on your material, or you can refer to a cutting chart.

Further, it is important to ensure that the material is properly secured to the cutting bed as a loose or warped material will cause cutting issues.

What do you do if a laser cutter catches on fire?

When a laser cutter catches on fire, it can be an extremely frightening and dangerous situation. The best thing you can do is turn off the machine immediately, unplug it from the power source, and evacuate the area. It’s also important to make sure that any non-essential people are out of the immediate area.

Once it is safe to do so, a trained technician should inspect the machine and any other equipment that might have been involved in the incident. The technician can check for signs of damage and assess the extent of the fire.

Conclusion

Taking the Time to Troubleshoot

Troubleshooting is an important part of laser cutting, so it pays to take the time to really look into the causes of any issues you might have. If you have a problem with your machine, the first thing you should do is stop the machine and any other processes that could be related. This will help you isolate the issue and make it easier to identify what is wrong.

While taking time to troubleshoot can be frustrating, it is also essential to ensure the safety of your employees and to make sure that production runs smoothly.

Maintaining a Laser Cutter for Successful Operations

When it comes to maintaining a laser cutter for successful operations, there are a number of things that you can be doing to ensure that you have a smooth and successful experience. First, you should make sure that the laser is properly serviced and maintained. That includes regular cleaning, replacement of worn parts, and lubrication.

You should also make sure that you are following all of the safety policies and procedures that are associated with operating the laser cutter. This includes proper use of protective gear, making sure that you have the correct power settings for the materials you are cutting, and more.