Achieve show stopping results with laser cutting and fabric! Laser cutting has revolutionised how we work with textiles and create intricate and beautiful designs. Whether you’re a professional craftsman or simply enjoying the creative possibilities of laser cutting – here are our top tips for creating impressive projects with laser cutting and fabric.

Getting Started

Choosing the Right Fabric

When it comes to laser cutting and fabric, choosing the right fabric is key to creating a show stopping project. The type of fabric you choose will affect the look, feel and durability of the finished project, so it’s important to choose wisely. Lasers are capable of cutting a variety of fabrics, from delicate chiffons and silks to more robust materials like denim and leather.

Selecting a Cutting Technique

fabric When it comes to selecting the right cutting technique for your project, laser cutting and engraving is usually the preferred option. With a laser cutter you have the ability to make precise cuts into almost any kind of material. Laser cutters allow for detailed designs and intricate patterns which can be used to create show-stopping projects.

When working with fabrics, laser cutting and engraving is the perfect way to create beautiful patterns and detailed designs.

Creating the Design

Designing for Laser Cutting

projects for beginners Designing for a laser cutter project can be intimidating for beginners. To help, here are some tips for creating show-stopping projects with laser cutting and fabric. When it comes to designing a laser cut project, the most important factor to keep in mind is compatibility.

Select a design that is laser friendly and compatible with the material you’re cutting. Some fabrics and materials, like leather, require specialized settings and may not be suitable for all laser cutter settings. While designing a project, consider the size and complexity of the design, as well as the speed of the cutting and engraving process when selecting the material for the project.

Understanding Basic Laser Cutting Parameters

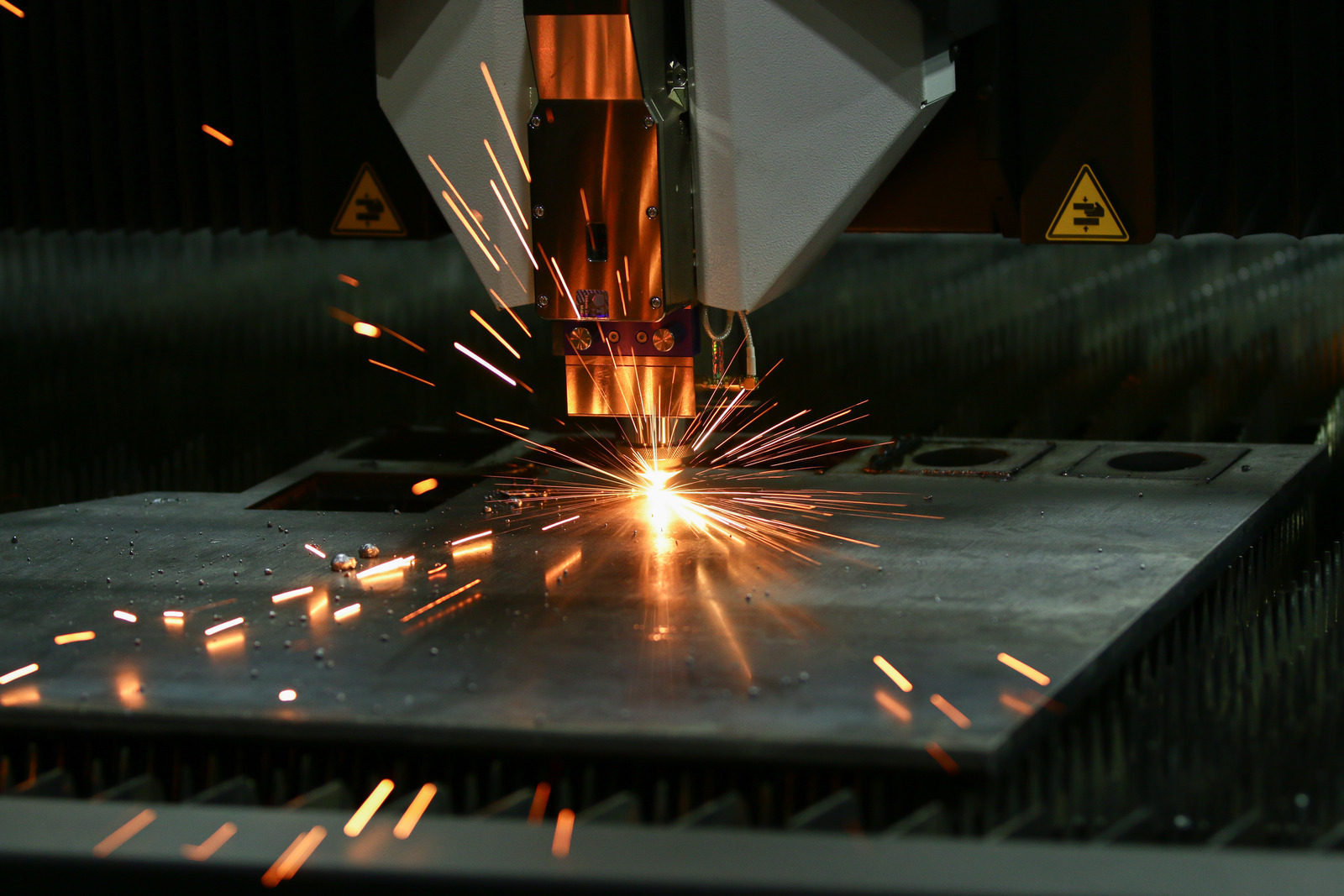

When creating amazing projects with laser cutters and fabric, it is important to understand a few basic laser cutting parameters in order to get the desired outcome. Laser cutters use high-powered beams of light to cut, engrave, or etch materials such as fabric and other materials. In order to get the desired output, it is important to understand the different components of the laser cutting process.

First, let’s consider the type of laser used in the cutting process.

Executing the Project

Safety Tips for Laser Cutting and Fabric

safety When preparing for a project involving laser cutting and fabric, safety should always be your number one priority. Working with a powerful laser cutter can be dangerous as the intense light from the laser can cause serious burns, eye injuries, and even fires. Therefore, it is important to take the necessary precautions while using a laser cutter to ensure an enjoyable and safe experience.

First, it is essential to have the right equipment and protection when using a laser cutter.

Choosing the Right Laser Cutter

for fabric Choosing the Right Laser Cutter When it comes to creating show stopping projects with laser cutting and fabric, the first step is choosing the right laser cutter. There are several different types of laser cutters available, depending on the type of project you are creating. For instance, if you are creating intricate designs with fabric, you may need a more powerful machine such as a CO2 laser cutter.

Setting Up the Cutting File

fabric Creating show-stopping projects with laser cutting and fabric can be a daunting task, especially since many of them require precise cuts and careful planning. But with the right tools and techniques, you can make a statement-making project that is sure to get noticed. One of the first steps to creating these projects is setting up the cutting file.

While this task may seem daunting, with a few basic steps you can get a laser cutter file up and running in no time.

Cutting the Project

fabric When it comes to creating show stopping projects with laser cutting and fabric, executing the project is half the battle. One of the most important components is the actual cutting. This is usually done with a laser cutter, which uses lasers to precisely cut out custom shapes, patterns, and designs in a variety of materials, including textiles.

The first step in laser cutting fabric is the preparation. This involves setup of the laser cutter, including loading the material, choosing the settings, and positioning the fabric for the maximum yield. Once this step is complete, the laser cutter is ready for the cutting process.

Finishing the Project

Finishing Techniques

software Finishing Techniques Once you’ve used a laser cutter to produce an excellent and detailed project, it’s time to finish your work! The great thing about using a laser cutter to create detailed and intricate fabrication is that you don’t always have to do a lot of work to make the project look amazing. One way to finish a laser cutter project is finishing with laser engraving.

Laser engraving is the perfect way to add that extra bit of detail and give your project that spark of uniqueness.

Adding Embellishments

fabric Many crafters have discovered the value of laser cutting and fabric when it comes to creating show-stopping projects. By combining the precision of laser cutting with the beauty of fabric, you can make stunning decorations and presents. But if you really want to stand out, you should consider adding some embellishments with laser engraving.

Which fabric is best for laser cutting?

fabric When it comes to laser cutting fabrics for your projects, it’s important to choose the right fabric for the job. Not all fabrics will work with a laser cutter, so it’s important to know which ones will give you the best results. Here are some tips to help you choose the right fabric for your laser cut projects.

Nylon and Polyester Fabrics: Nylon and polyester fabrics are among the most popular materials to use with a laser cutter. These materials are easy to work with and offer a great deal of accuracy in the cuts.

What are the safety issues you need to be aware of when using a laser cutter?

safety When working with laser cutters, it is important to take safety precautions to ensure the project turns out perfectly and the environment is safe for everyone. Here are some things to keep in mind when using a laser cutter for projects. First and foremost, always be sure to wear protective gear, such as safety goggles and respirators, when using the laser cutter.

Conclusion

Summary of Tips

fabric In this blog, we explored tips for creating show stopping projects with laser cutting and fabric. To summarize, here are a few key tips to keep in mind during your project: -Safety is of utmost importance when working with a laser cutter. Always follow the safety instructions related to the equipment.

-Choose the right fabric for your project. Thin and dense fabrics are ideal for laser cutting, while thicker and less dense fabrics may cause laser distortion. -Using a protective cover sheet can help keep your fabric protected when using a laser cutter.

-Choose your design carefully.

Looking Ahead to Future Laser Cutting Projects

fabric As you look ahead to future laser cutting projects, it’s important to consider the range of possibilities available. With laser cutting, you have the freedom to create show-stopping projects that are designed your way, from wooden keys to leather wallets, wood signs to fabric bags. And don’t forget the endless possibilities of laser engraving.

You can create intricate designs into flat, two-dimensional items with complex detail, depth, and character. The possibilities are endless when it comes to laser cutting projects. When you combine laser cutting with advanced technology, like 3D printing, you can create unique and unexpected pieces that are sure to impress.