This comprehensive guide is designed to give an in-depth overview of the basics of laser cutting. We will provide answers to such questions as: What is laser cutting? What types of materials can be cut? What types of laser cutting applications can be used? We’ll also discuss the design considerations and benefits associated with laser cutting. Finally, we will discuss how laser cutting may be used within a manufacturing environment. By the end of this guide, you will have a strong understanding of laser cutting and the associated benefits. Let’s dive in!

Benefits of Laser Cutting

Cost Savings

Cost savings is one of the biggest benefits of laser cutting. With laser cutting, you don’t need to buy special tools and expend resources trying to cut material manually. Instead, you can use a laser cutter to quickly, accurately and precisely cut any material that you need.

Laser cutting also supports automation; it works quickly and can even be run overnight. This can help you reduce labor costs and minimize production delays.

Accuracy

Accuracy is one of the major benefits of laser cutting. Laser cutters have incredibly precise cutting capabilities, making them incredibly useful for intricate parts or detailed designs. With the right set up, laser cutters can cut parts with a precision of +/- 0.02 mm.

This level of accuracy is especially useful when creating intricate shapes or patterns. This can help save time and money when manufacturing components, since less material is wasted and the parts are much easier to assemble.

Production Speed

Production speed is an important benefit of utilizing laser cutting technology. Laser cutting machines are capable of producing precision-cut parts at an incredibly fast rate of speed. An industrial laser cutter can typically cut metal or other types of materials thousands of times faster than traditional methods of cutting, such as sawing and machining.

In some cases, a laser cutter can produce parts in a matter of seconds, compared to hours or even days with traditional methods.

Laser Cutting Equipment

Laser Cutting Machines

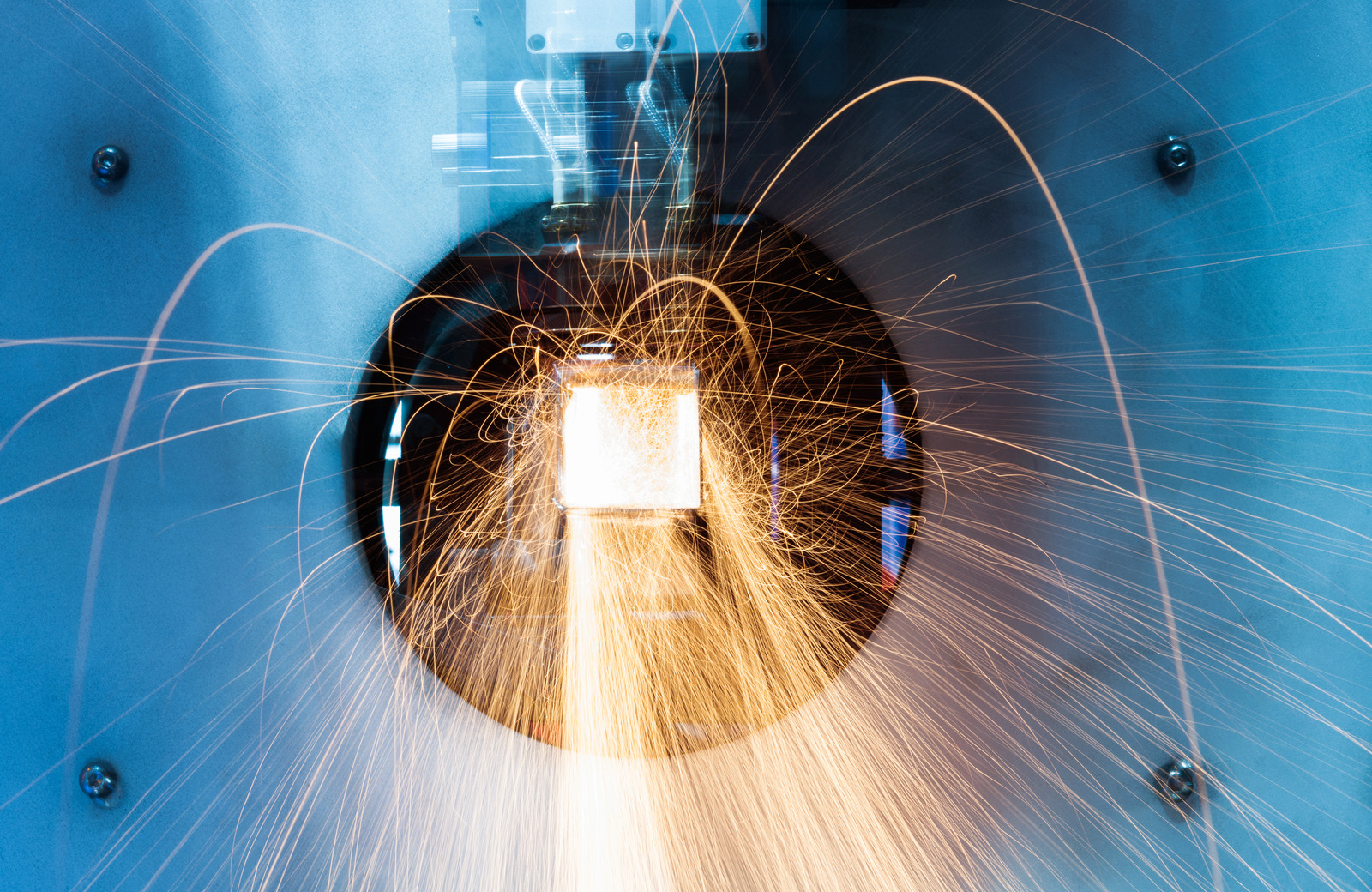

Laser cutting machines are used to precisely cut a variety of different materials. In short, a laser cutting machine is a tool that creates designs on surfaces with a directed laser beam. Unlike other cutting and engraving tools that use mechanical actions, such as blades and chisels, to cut and engrave, a laser cut creates an extremely precise end result without the need for multiple passes and time-consuming detail work.

There are many different types of laser cutting machines available on the market today.

Components

When it comes to the basics of laser cutting, having the right equipment is key. The main components of a laser cutter are its laser source, a cutting surface, motion control technology and safety features. The laser source is the heart of the cutting process.

It emits a beam of light of a specific wavelength and power. The type of laser you use affects the material you are able to cut and the speed at which you can cut. Common laser types used in laser cutters are CO2 and fiber lasers.

The cutting surface is the platform that is used to hold the material that is being cut.

Safety Considerations

Laser cutting is an advanced method of cutting materials with high precision and accuracy. Laser cutting is accomplished by directing a laser beam at a material, which is then melted or burned away. The laser cutting process is well suited for cutting sheet metal, plastics, and other materials. With the right laser cutting equipment and an understanding of basic safety considerations, this type of manufacturing can be easily completed.

- Always wear safety glasses/face shields when using laser cutting equipment and when working in the immediate area of the machine. Wear thick-soled shoes and cotton, polyester, or other non-synthetic clothing. These materials won’t melt or ignite if exposed to the laser beam. Abide by all instruction given by the manufacturer for all safety features, including emergency stops, power locking doors, and ventilation systems. Utilize personal protective equipment (PPE) such as a fire retardant lab coat and Kevlar gloves. Familiarize yourself with the possible hazards and safety protocols of laser cutting to ensure your safety.

Materials and Design Considerations

Materials

Materials are perhaps the most important part of laser cutting. Different types of materials can be cut and engraved with a laser cutter, with some materials being more suitable than others. The types of materials most commonly used are non-metal materials such as acrylic, wood, and paper, but many other materials, including thin metals and leather, can also be cut and engraved.

When considering materials, it is important to understand the different properties of the material.

Design

When it comes to designing a laser cutter project, it is important to have a clear plan and purpose before getting started. When using a laser cutter, you should consider the properties of the materials being cut, the power of the laser, the design, and the accuracy you are looking to achieve. When designing a laser cutting project, the first thing to consider is the material or materials used in the project.

In most cases, the material should be rated for laser cutting.

What is the principle of a laser cutter?

The principle of a laser cutter is simple. A laser beam – either a CO2 gas laser or a solid-state YAG/Diode laser – is directed onto a material of choice, with the source of the beam accelerated by mirrors and directed to a specific location. This stream of laser energy then heats up the material and causes it to evaporate.

The laser can have its power increased and the beam focused to increase the precision and speed of cuts, allowing it to be used for a variety of applications.

Conclusion

Summary

In this comprehensive guide, we’ve gone through the basics and some of the more advanced aspects of laser cutting. We’ve discussed the materials that are used, like metals and plastics, as well as the design specs needed for a good laser job. In addition, we discussed the various materials that can be used to create a tight seal when laser cutting.

Summary of Benefits

Conclusion: At the end of the day, laser cutting is an incredibly useful tool for a wide range of applications. Its accuracy, efficiency and precision make it a great choice for cutting even the most intricate shapes. It is also beneficial for its affordable cost.

Laser cutters are relatively affordable and don’t require the same level of maintenance that other traditional cutting machines do. Laser cutting is also very versatile since it can be used with a variety of materials, from wood and acrylic to paper and fabric.

Final Thoughts

In conclusion, laser cutting is a powerful tool used in a variety of sectors, from manufacturing and engineering to art and design. It has revolutionized the way products are manufactured, allowing companies to produce complex shapes and intricate patterns with a higher level of accuracy and consistent results. With the rapid advancement of laser technologies, various materials can now be cut with laser cutters.

Many companies are taking advantage of this technology to make high-quality, cost-effective parts quickly and efficiently.