Laser cutting is a precise and versatile technology that is gaining widespread popularity in the world of textiles and fabric. It is capable of producing intricate designs with ease and can produce intricate patterns and shapes with great accuracy and detail. In this article, we will explore how laser cutting works and what makes it an ideal option for textiles and fabrics. We will also discuss the materials and processes that are used to create stunning laser-cut projects. Finally, we will review the safety considerations associated with laser cutting.

Getting Started

Design Process

The design process of laser cutting textiles and fabrics is an important part of producing creative and beautiful laser cut fabric items or garments. Laser cut fabric is a great way to create intricate, eye-catching designs that are not easily achievable with traditional cutting methods. The first step in the laser cutting process is to design the artwork that you want to cut out of the fabric.

This could be anything from simple shapes and outlines to complex designs with multiple layers.

What equipment do I need?

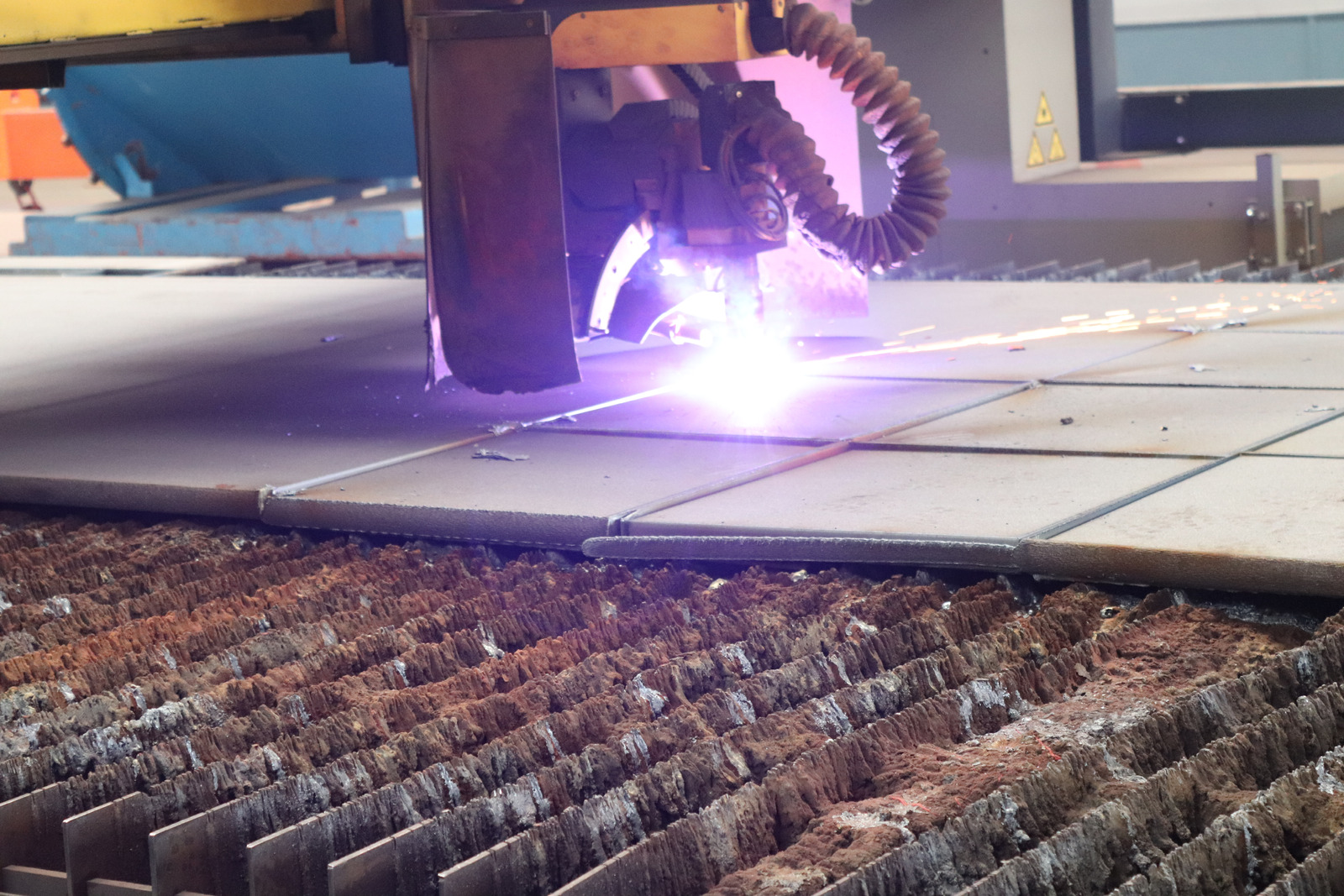

and Fabrics If you’re looking to get started with laser cutting textiles and fabrics, you’ll need the right equipment. The most important piece of equipment you’ll need is a laser cutter. Laser cutters use high-powered beams of light to cut or engrave materials, including textiles and leather.

A laser cutter is ideal for quickly and accurately cutting intricate pieces of fabric as well as engraving unique patterns on them.

Safety Protocols

and Fabrics Safety is always of utmost importance when working with laser cutters, especially when dealing with fabrics, textiles, and other materials that may present additional hazards. When laser cutting fabrics and textiles, it is important to pay attention to laser safety protocols and make sure that you are in an appropriately ventilated space and observe safety precautions. Always double-check that you have the proper personal protective equipment when using your laser cutter, like goggles and gloves.

Without proper protection, fibers, heat, and fumes can be strong irritants that can affect the skin, eyes, and lungs. Practice caution in the setup of your material.

How to Laser Cut Textiles & Fabrics

Prepping Material

and Fabrics When it comes to laser cutting textiles and fabrics, proper preparation of the material is key for successful results. This includes cutting the material to the desired size, as well as organizing it for best cutting performance. First, measure and cut the fabric to size.

Using a ruler and a rotary blade or fabric scissors, adjust the pieces to the right size to fit your cutting board or mat. Make sure all the pieces are the same size and in order. Next, organize the fabric on the cutting board or mat.

Setting Up the Machine

and Fabrics Setting Up the Machine When it comes time to setting up a laser cutter to cut fabric, you’ll need the right machine and supplies. There are a few materials that must be ready before you can begin. First and foremost, it’s important to have a quality and reliable laser cutter that is equipped with the appropriate engraving and cutting tools for the specific needs of fabric laser cutting.

Performing the Cut

and Fabrics Performing the Cut When it comes to laser cutting textiles and fabrics, the process is fairly straightforward. First, you need to create a digital design that you want to use as your template. The design should be vectorized, meaning it needs to consist of closed shapes that have corners instead of curves.

This is because the laser cutter won’t be able to accurately cut along curved lines. Once you have your design ready, you can start setting up your laser cutter.

Common Use Cases

Detailing

and Fabric Laser cutting textiles and fabrics is a process that involves precise cutting of fabric and other materials using a laser. It utilizes the power of a precise laser to cut intricate designs with a high level of accuracy. Laser cut fabrics or textiles tend to have an aesthetically pleasing look to them and can be used for a variety of purposes, from fashion garments to architectural features.

Embossing

and Fabrics Do you have an idea for an amazing, intricate design in fabric but have no way to make it come to life? With laser cutting, you can finally make all of your textile dreams come true! Laser cutting is the process of using a laser beam to cut materials like fabric, cardboard, and wood, as well as engrave on them.

To laser cut fabric, you need to first choose your pattern or design and then prepare the fabric by washing and stretching it.

Creating Custom Textiles and Patterns

Fabric Laser cutting is a fast and precise technology used to cut or engrave textiles, fabrics and other materials to create complex designs and patterns with extreme accuracy. Since lasers are able to provide much higher accuracy than traditional methods of cutting, using laser cutting is ideal for creating intricate patterns and designs. This makes it great for a wide variety of textiles and fabrics, from clothes and curtains to bags and rugs.

One of the most common uses for laser cutting is in the fashion industry, where it is used to quickly and accurately create clothing items with intricate patterns and designs.

What is meant by laser cutting?

and Fabrics Laser cutting is a process of cutting and engraving textiles, fabrics, and other materials with an intense beam of light from a laser, instead of a traditional knife or blade. This technology has revolutionized the way that fabric and textile arts can be made and manipulated, with remarkable precision and efficiency. It works by focusing a powerful beam of light on material, which is typically made of polyester or natural fiber, and using the laser’s heat energy to cut along a pre-selected pattern or design.

Conclusion

Summary of Benefits

and Fabrics When it comes to cutting textiles and fabrics, laser cutting is the go-to technique. This method is incredibly precise, which makes it ideal for intricate products, designs and patterns. Additionally, laser cutting is often extremely affordable, and can be achieved with a relatively small investment.

Tips for Success

and Fabrics In conclusion, if you’re looking to add laser cutting to your list of textile fabrication skills, there are a few tips and tricks that can help you achieve the most desirable results. Taking into account the type of laser cutter you are using, the thickness of the fabric you are attempting to cut, the speed and force settings you are using, and the types of fabrics you are working with, can all affect the overall outcome of your project.