The use of laser technology in industrial machining is on the rise and for good reason. Laser cutting offers numerous benefits when compared to traditional key machining processes. From its superior accuracy and repeatability to its cost-effectiveness and increased safety measures, laser cutting is a highly efficient and cost-effective method of producing parts and components. In this article, we will explore the many benefits of laser cutting for key machining.

The Mechanics of Laser Cutting

How laser cutting works

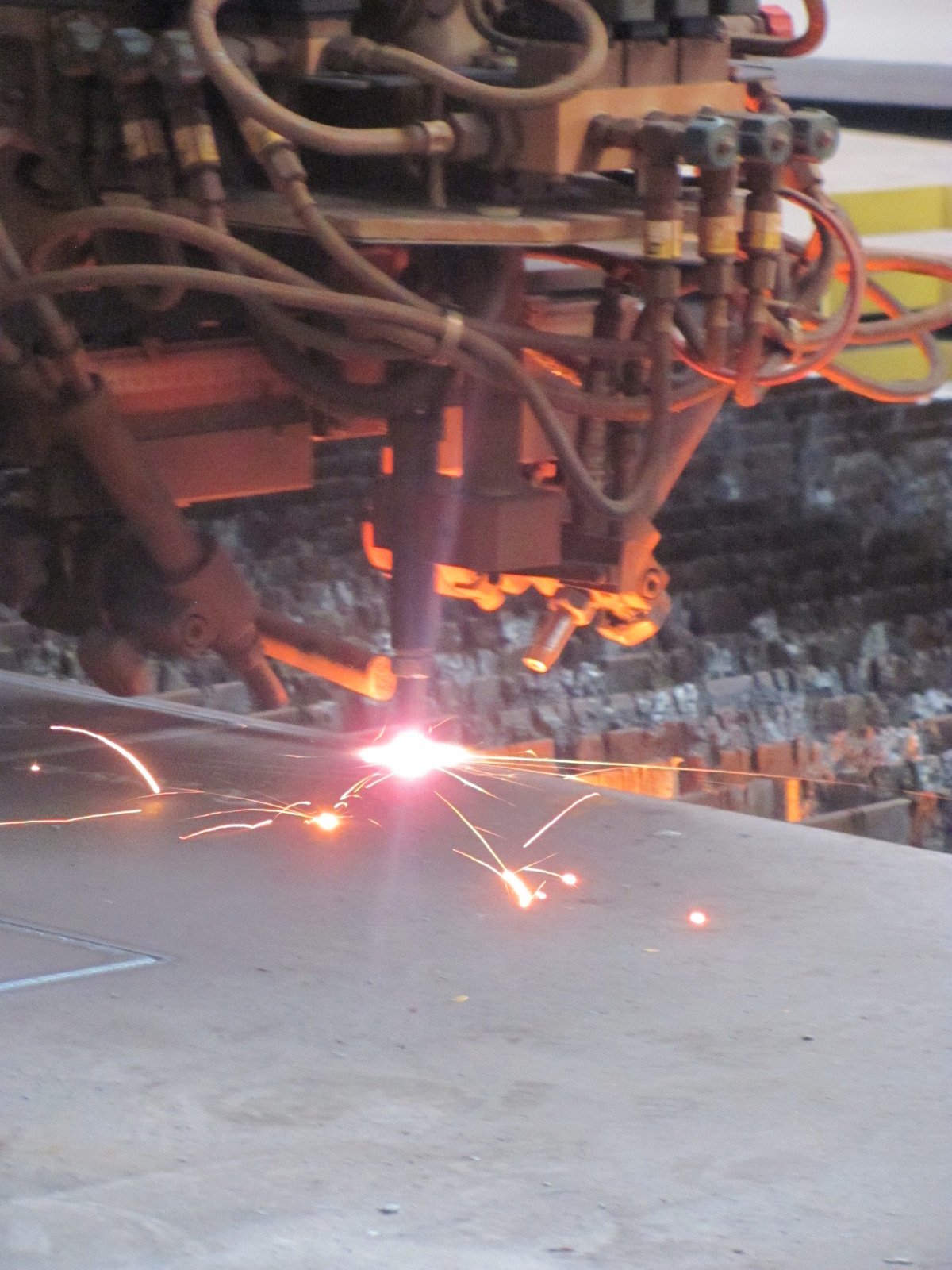

Laser cutting is one of the most advanced technologies available for machining key components. It harnesses a high-powered laser beam to produce intricate cuts and designs with amazing accuracy and precision. Laser cutters are designed to work within a given material’s mechanical and thermal limitations to produce the desired product.

The process of laser cutting begins with the software. The machine’s computer will input the selected design onto its cutting bed and the laser beam will move according to the program. The beam will then use a focused beam to reduce the material through a combination of heat and extreme pressure.

The kind of laser cutter used to shape the material also affects the process.

Advantages of laser cutting over other machining techniques

Laser cutting is a technology that has revolutionized the machining industry. It is a process of using a laser beam to cut and shape metals and other materials into the desired shape. Laser cutting offers many advantages over traditional machining techniques. It is capable of giving accurate results with very few errors and can produce complex shapes with great precision.

- Make sure your laser cutting machine is equipped with the right power and optics for your desired application. Different materials require different settings to achieve the best results.

- Always wear safety equipment when operating the laser cutter. In addition to safety glasses, safety gloves and other protective apparel should be worn.

- Make sure to use the right cutting parameters when cutting with the laser. Too much power or the wrong feed rate can result in poor cuts, or even potential fire danger.

- Regularly clean the bed of the laser cutter as it accumulates debris from the cutouts. This helps ensure clean, detailed cuts every time.

- Utilize a CAD/CAM package to design and program parts for efficient yet precise cutting. This allows for maximum accuracy and repeatability with the cutting processes.

The Benefits of Laser Cutting For Key Machining

Time savings and production costs

When it comes to the machining of keys, laser cutting has become a popular option due to the time savings and production costs it offers. Laser cutters offer precision and accuracy when cutting the necessary parts for a key, thus producing a high-quality end-product. In addition to saving time, laser cutters also offer cost savings as they consume less energy than traditional methods of machining.

By utilizing a laser cutter for key machining, there is also a reduction in labor costs, as certain parts of the process can often be automated using a computer program.

Accuracy and precision

The use of laser cutting for machining is growing in popularity due to its impressive accuracy and precision. Laser cutters utilize a high-powered laser beam to cut through materials, allowing for the controlled and precise cutting of complex shapes with minimal waste. Laser cutters can also be used to cut a variety of materials, including steel, aluminum, titanium and even plastics.

When it comes to machining, the accuracy and precision of laser cutting is unmatched by other traditional cutting methods. Laser cutters can cut parts with a high degree of accuracy due to the fact that the laser beam focuses on a very small area, allowing for greater precision when creating intricate shapes and designs.

Repeatability

Repeatability is one of the key advantages of laser cutting for key machining. It ensures the same piece of material is consistently cut to the same dimensions. This is due to the high accuracy of today’s laser cutters.

Laser cutters are equipped with sensors which use the beam to precisely measure the material being cut. This allows for extremely precise measurements and repeated cuts within very high tolerances. This makes for quick and accurate production times, with little to no waste created during the cutting process.

Additionally, as multiple cuts can be made with no degradation in quality, it is not necessary to reproduce the cuts multiple times.

Conclusion

Summary of the advantages of laser cutting for key machining

Laser cutting is an efficient and cost-effective way of producing precision parts. It can be used for a variety of machining operations, including key machining. Using laser cutters for key machining comes with multiple advantages, including increased accuracy and speed, greater versatility, improved safety, and reduced costs.

Accuracy is key when it comes to machining components and parts. Laser cutters provide a high level of accuracy, as they can be programmed to make cuts with a precision of up to 0.01mm. Additionally, because laser cutters are computer-controlled, it’s easy to transfer files between machines and make multiple copies of complex designs.

Final thoughts and considerations

When it comes to key machining, laser cutters offer a number of key advantages. These cutters provide greater precision and accuracy compared to other cutting processes. In addition, the speed and affordability of laser cutting provide a cost-effective solution to many key machining tasks.

Finally, laser cutters have the potential to reduce the wastage of valuable materials, thereby helping to reduce overall costs.