Vinyl records have long been an important part of the music industry, but recently they have become even more popular due to the resurgence of vinyl fans. If you’re looking for a new way to cut vinyl records and make them look, sound, and feel just like the originals, then laser cutting is the answer. In this article, we will explore why laser cutting is the best way to create new vinyl records and the advantages that come with it.

Benefits of Laser Cutting for Vinyl Records

More precise and detailed cutting

When it comes to cutting vinyl records, laser cutting is the best way to create new records that have incredibly precise and detailed cuts. With traditional cutting methods, things like jagged edges or warped pieces are very common. But with a laser cutter, you get a much cleaner and smoother cut, so the finished product looks much better.

Increased durability

When it comes to producing vinyl records, using a laser cutter is becoming the go-to method. One of the main reasons why is because of its increased durability. By using a laser cutter, the cut vinyl records can stand up to wear and tear better than records that have been cut via traditional methods.

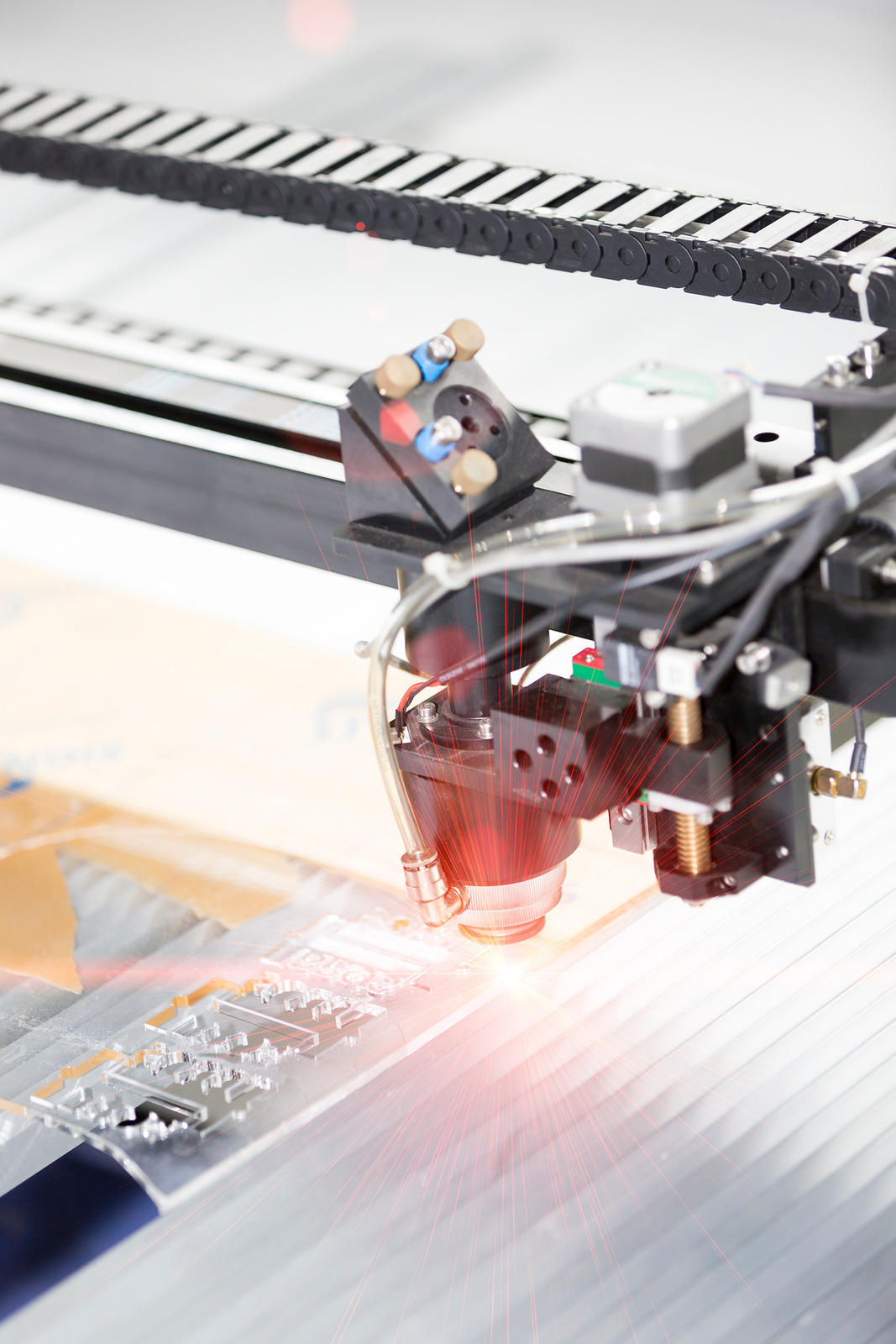

This is due to the precision of the laser cutting process. The laser cutter uses an intense light beam to cut through the vinyl, and the exactness of this process can be extremely precise. A laser cutter can cut vinyl records at a 0.

Better sound quality

When it comes to making new vinyl records, laser cutting is the go-to method for achieving the best sound quality. While traditional cutting methods such as hand-cutting and stamping are good for creating one-time production runs, nothing can beat the precision of a laser cutter when it comes to cut vinyl records. By using a laser cutter, engineers can produce records that are virtually indistinguishable from the original.

History of Vinyl Records

Origins

The origins of vinyl records go back to the late 19th century, when inventors first began experimenting with sound recordings on cylindrical surfaces. The earliest versions of this technology were limited and soon supplanted by more robust, commercial vinyl records. However, it wasn’t until the 20th century when laser technology enabled commercial production of vinyl records that the industry could accurately cut records in high volume, and at better quality.

Today, laser cut vinyl records are the preferred method for cutting vinyl. The lasers used for cutting records have advanced over time, becoming much more precise and allowing for higher quality recordings.

Development of technology

Cuts made with a laser cutter provide a much better quality product when creating a vinyl record, making them the best way to create new vinyl records for today’s market. The use of laser technology in the production of vinyl records began in the 1960s, albeit with limited success. It wasn’t until the development of a more powerful laser cutter in the late 80s that the possibility of using laser technology to cut vinyl was realized.

Arguments for Traditional Vinyl Record Production

Higher cost

When it comes to creating new vinyl records, laser cutting is a better and more cost-effective method than traditional vinyl record production. This is largely because of the cost implications associated with using a laser cutter to cut vinyl records. Laser cutters are significantly more expensive than traditional vinyl record production tools, and require a large upfront investment for any production facility.

Furthermore, the laser cutter requires more time and effort to properly use, and requires an experienced operator who needs to have a good understanding of how to use it.

Lower quality

When it comes to creating vinyl records, one of the best ways to do so is to use a laser cutter. Laser cutting is an incredibly precise, accurate, and efficient way to cut vinyl records. It is a much better method than the traditional way of creating vinyl records which require a stamping machine, as the laser cutter creates more precise cuts on the vinyl and creates records with much higher quality.

The laser cutter works by using a focused laser beam to cut the shape of the vinyl record accurately. This laser beam is exactly focused onto the vinyl which makes it easy to achieve an incredibly precise cut.

Can you make vinyl records with a laser cutter?

Yes, you can absolutely make vinyl records with a laser cutter–it’s one of the best new methods of producing records. Laser cutting is a much better choice than the traditional cutting methods, as it is extremely precise and produces a far more detailed and accurate cut. The cutting process is also a lot faster, allowing you to produce more records quickly and cost effectively.

The laser cut vinyl records are also much higher quality than records created with other cutting systems. A laser cutter is able to create smaller and more intricate details, resulting in better audio fidelity for the end product.

Conclusion

Laser cutting is the superior approach for creating vinyl records

In conclusion, laser cutting is the superior approach for creating vinyl records. Using a laser cutter, vinyl records can be cut with a much higher degree of accuracy and precision than any other method. This makes laser cutting the ideal option for creating a vinyl record with the best possible sound and quality.

The laser cutter can also be used to cut vinyl records in a variety of shapes, sizes and designs that are not possible with traditional methods. With a laser cutter, you can create a unique product and one of a kind vinyl record that will be difficult to find anywhere else.

Overall benefits of laser cutting for vinyl records production

a When it comes to the production of vinyl records, laser cutting is by far the best way to go. It offers a number of advantages that make it superior to traditional ways of cutting vinyl records. For starters, a laser cutter can cut vinyl records with a much greater level of precision than traditional methods, giving the finished product a better sound quality and a longer lifespan.

Additionally, a laser cutter is much more efficient and cost effective when compared to more traditional methods, which makes it a more viable option for producers and labels.

Impact of technology on the vinyl record industry

The impact of technology on the vinyl record industry has been tremendous. Until a few years ago, the only way to create vinyl records was to physically press them in a pressing plant. Now, thanks to the introduction of a laser cutter, it is possible to cut vinyl records with a much higher precision and accuracy.

This advancement in technology has allowed manufacturers to cut vinyl records much faster than before while also producing results that are of better quality.