In the world of music recording, we now have access to a variety of processes and technologies to help us capture and playback sound. This includes the choice between traditional vinyl record cutting and more modern laser cutting techniques which offer a more precise and precise result. In this article, we will compare these two methods and discuss the advantages of each. By the end, you will be equipped with the knowledge to confidently decide which method is best for your project. Let’s get started!

Advantages of Traditional Vinyl Record Cutting

Energy Efficiency

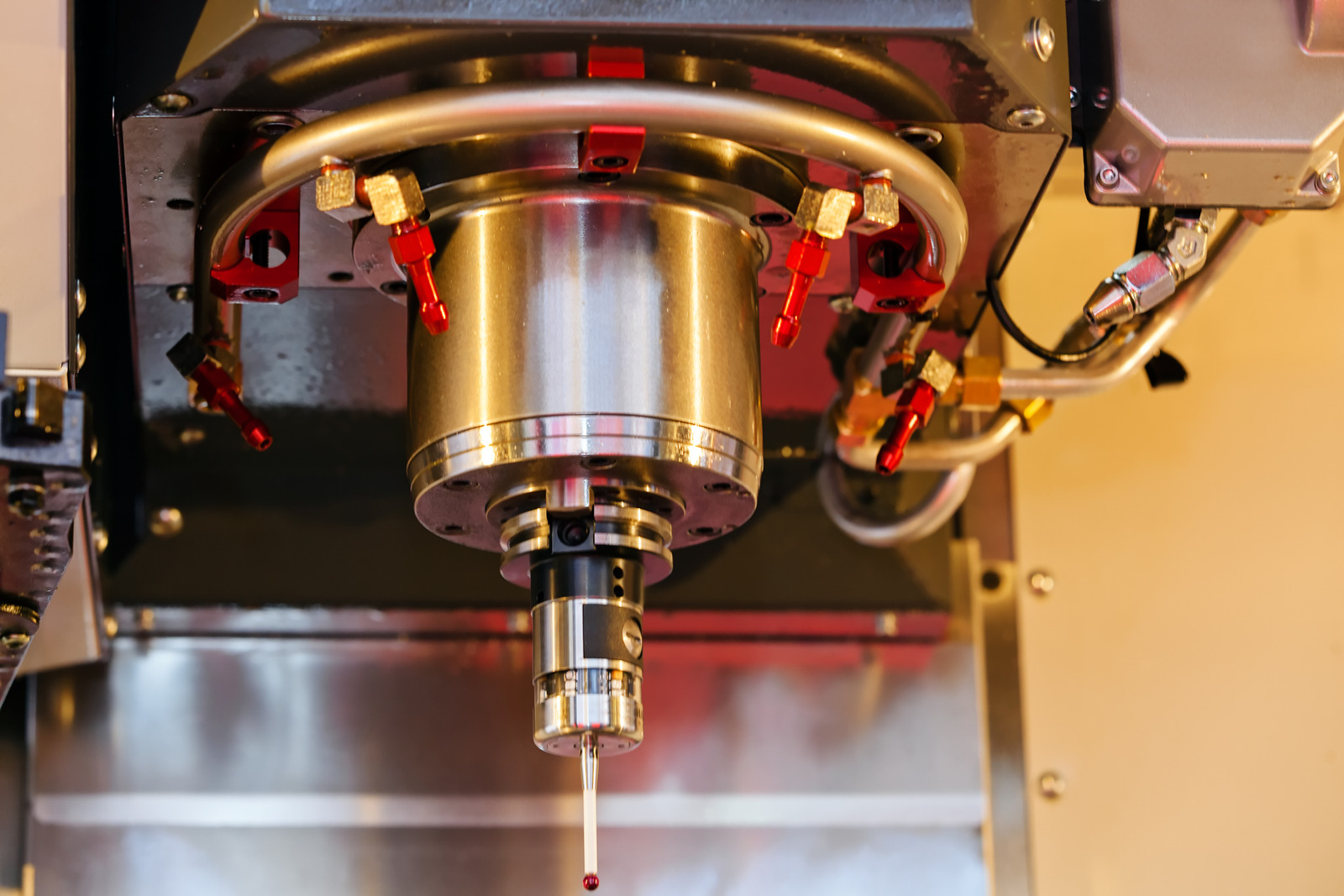

When looking into the advantages of traditional vinyl record cutting vs. laser cutting, one key component to consider is energy efficiency. Traditional vinyl record cutting is much more energy efficient than laser cutting because it requires less energy to process the material. Vinyl records are created by a mastering engineer who uses software to digitally map recorded music, and then CNC machine or a vinyl cutter is used to cut the material into a single shape.

In comparison, laser cutting is used to create a 3D image on a material that is considered unsafe to cut or engrave with a laser.

Cost-Effectiveness

on the record When it comes to cutting vinyl records in a cost-effective way, traditional vinyl record cutting is the way to go. As opposed to laser cutting, traditional vinyl record cutting is far less expensive, and can even be used in cases where cost is not a huge factor. With traditional vinyl record cutting, material like cardboard, ethylene vinyl acetate (EVA), and other types of vinyl can all be cut accurately and efficiently.

Reliability

cut by the traditional lathe When it comes to reliability, traditional vinyl record cutting has been the industry standard for decades. This method of cutting audio using a vinyl lathe involves a mastering engineer digitally mapping audio information into a groove on a vinyl blank. The vinyl blank is then cut using a specialized tool mounted on a motor to freshen or ‘re-cut’ the soft vinyl.

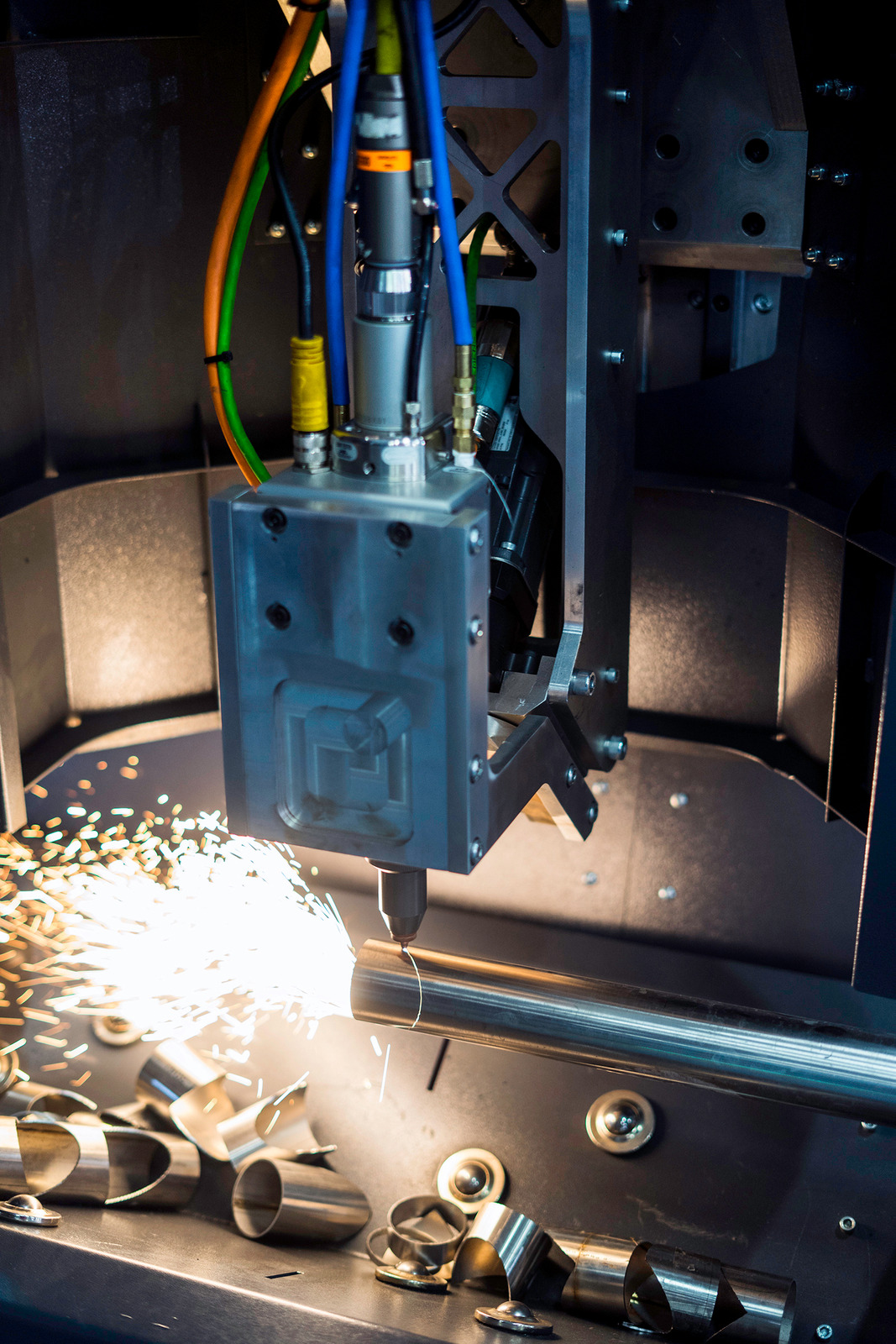

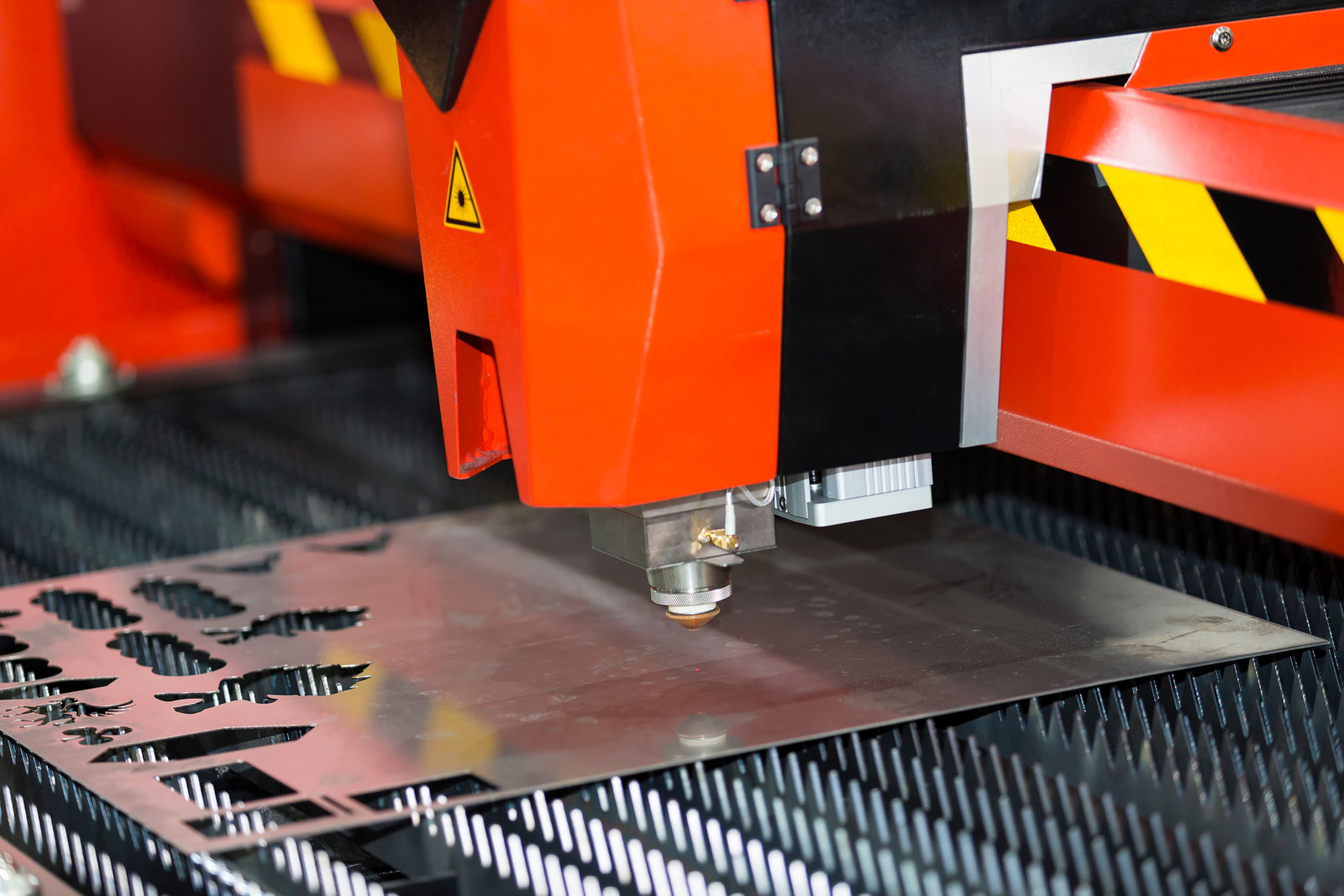

This method eliminates the potential of poor quality cutting and ensures structurally sound records. In contrast, laser cutting creates a 3D image on the blank vinyl discs using a laser cutter.

Disadvantages of Traditional Vinyl Record Cutting

Technical Limitations

When it comes to traditional vinyl record cutting, there are a number of technical limitations that can hamper an engineer’s ability to achieve a great sounding record. One of the main issues is that the cutting process relies on a single cutting shape, which has its limitations. This means that when mastering an album, the engineer has to consider how many grooves will fit on the record and how to make them all fit within a single shape.

This can lead to a lot of compromises that can ultimately result in a sub-par record.

Quality Consistency Issues

Traditional vinyl record cutting is a laborious and often unpredictable process. The quality of the resulting records can vary widely. Sometimes, a single batch of records will arrive with vastly different sound qualities.

This is caused by the inconsistency of traditional cutting techniques. Rather than manually pressing a cutting needle into wax, vinyl record cutting has been revolutionized with laser cutting technology. Laser cutting is much more precise than the traditional method and provides a consistent quality which is not achievable with the traditional procedure.

With laser cut records, the sound quality of each record is the same, regardless of the batch they’re part of.

Advantages of Laser Cutting Technology

Improved Quality

on the vinyl When it comes to improved quality of records, traditional vinyl record cutting is being replaced by laser cutting technology. With laser cutting, engineers are able to digitally map music with software, and then laser cut records that can have much greater detail and clarity than those cut with a traditional vinyl cutter. Laser cutters are also more adaptable to cutting materials that are considered unsafe to cut or engrave with a traditional cutter.

The laser cutting process is also much more precise than traditional vinyl cutting and can break through the single shape of the traditional wall clock.

More Stability

When talking about stability in cutting vinyl records, traditional methods of cutting vinyl records rely on a mastering engineer who uses software to digitally map it onto a vinyl disc. This mapping is then completed by a cutting stylus, which is a diamond-tipped tool that engraves each groove individually into the vinyl. While this works well for cutting vinyl, it can become tedious and time-consuming, especially if complex patterns are desired.

Greater Range of Innovative Designs

Using laser cutting technology instead of traditional vinyl record cutting or engraving has opened up a greater range of possibilities for innovative designs. With traditional cutting, engineers mapped out the music digitally using software, but with laser cutting, a mastering engineer can more accurately define the exact location on the two sides of the groove wall for the music, allowing for more intricate and precise designs. The laser cutting process also allows for a wide range of materials that can be used that were previously considered unsafe to cut or engrave with a laser.

Disadvantages of Laser Cutting Technology

High Costs

When it comes to traditional vinyl record cutting, the process has remained relatively the same for decades and involves a mastering engineer digitally mapping the sound of the recorded music to plates that are cut into vinyl using a lathe. This results in a product made of a single piece of material, where the grooves in the vinyl are run in a continuous wall in a clockwise pattern. On the other hand, laser cutting technology has opened up new opportunities for creating records that are more intricate and might sound better than traditional vinyl.

One of the major drawbacks to laser cutting technology is the high costs associated with it.

Difficulty With Single Track Recordings

When it comes to traditional vinyl record cutting vs. laser cutting, one aspect to consider is the difficulty with single track recordings. This is especially true when trying to create a 3D image on a wall clock. With traditional vinyl record cutting, the single shape of the clock is easy to cut and engrave with a cutting machine.

However, laser cutting presents a greater challenge as it breaks through a single shape and is considered unsafe to cut or engrave with.

Why vinyl records are better than digital?

Vinyl records have recently made a resurgence in modern music formats, rivaling the digital sound of MP3s and CDs that have dominated the music world for decades. While the digital sounds of these formats are convenient, vinyl records stand apart due to their unique sound factor. This is due to the characteristic “warmth,” which is created when a stylus is gently guided along the grooves of a record.

This means that each record is unique, based on the individual recording and mastering engineer who created it.

Is vinyl more accurate than digital?

are uniform When comparing traditional vinyl record cutting to laser cutting, there is one main question to consider: is vinyl more accurate than digital? It’s an important question to consider, as accuracy is one of the key factors in making quality records. The traditional method of vinyl record cutting involves a mastering engineer who digitally maps out the recorded material using software.

Does original vinyl sound better?

, the exact geometric shape of the waveform Many audiophiles claim that the original vinyl records sound better than digitally remastered versions. The reason is that traditional vinyl cutting is done with a lathe that has a cutting stylus which is used to engrave a groove in a master record. The master record is then transferred onto a disc made from vinyl or polyvinyl chloride (PVC).

Conclusion

Summary of Pros and Cons

In summary, both traditional vinyl record cutting and laser cutting have their own unique pros and cons. Traditional cutting is a tried and true method with its advantage of being able to cut out deep and warmer sounding grooves. However, it is limited by how loud and clear of a sound it can produce since the groove is only a single shape.

On the other hand, laser cutting has the advantage of being able to create incredibly detailed 3D imagery that can result in clearer and louder sound, although it can be more expensive and difficult to create.

Recommendations For Digital Music Formats

When considering digital music formats, the traditional vinyl record cutting process has been around since the 1800’s and is still used in the modern age; however, laser cutting is becoming increasingly popular. With laser cutting, a mastering engineer uses software to digitally map the audio recordings, then the grooves are laser-cut into a material that is often considered too hard or unsafe to be cut or engraved using a traditional drill bit. Additionally, the laser cutting process can create a 3D image on the single shape of a traditional disc, giving it a more sophisticated look and feel.