If you’re looking for woodworking projects that take your passion to the next level, then exploring laser cut wood sheets is the perfect way to breathe new life into your ideas. Laser cutting technology does not only allow you to create intricate and detailed designs, but also has the versatility to create shapes and patterns that are impossible with traditional methods. In this article, we’ll explore the different types of laser cut wood sheets available and how they can help you unleash your inner creativity!

Types of Laser Cut Wood Sheets

Baltic Birch Plywood

services Baltic birch plywood is an excellent, versatile material for laser cutting services. It’s great for a variety of applications, from making prototypes to creating model parts and custom artwork. The material is made from extremely thin layers of birch wood that have been glued together for strength and stability, meaning it won’t warp like some other types of plywood.

MDF

MDF When it comes to laser cutting wood sheets, MDF (medium-density fiberboard) is a popular choice for cutting intricate details with a high degree of accuracy. MDF is made from compressed wood fibers and resins, providing it with a smooth, consistent surface that is ideal for laser cutting. This material is also known for its durability and resilience, making it a great choice for a wide range of applications.

When it comes to laser cutting MDF, the design is limited only by the cutting capabilities of the laser itself.

Acrylic

mdf When it comes to laser cutting wood sheets, acrylic is one of the most popular materials used. It is a versatile and durable plastic that is available in a wide variety of colors, shapes, and thicknesses. Plus, laser cutting acrylic sheets is fast, precise, and produces sharply defined patterns and cuts.

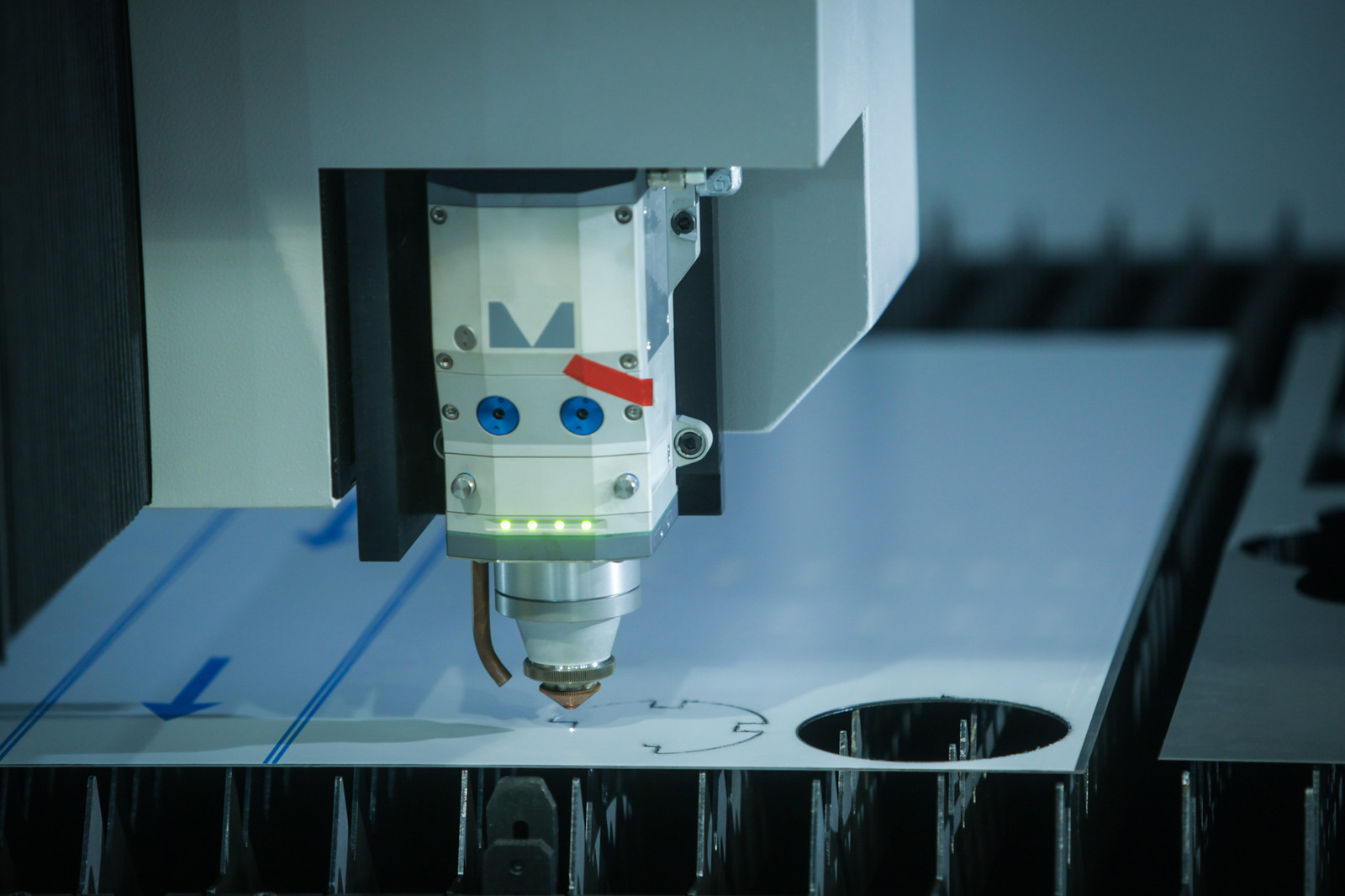

Acrylic laser cutting works by using a beam of high-energy light that focuses on the sheet to quickly and precisely cut it into whatever shape you have programmed into the machine.

Hardwood

wood When it comes to laser cutting wood, hardwood is a popular option. This type of wood is made up of a variety of wood species, such as oak, mahogany, and walnut, among others, and it offers unique advantages as compared to other wood types. Hardwood is highly durable and holds up well against wear and tear, which makes it a great option for laser cutting.

Unlike other wood sheets, hardwood is more resistant to warping, cracking, and splitting, even after the laser cutting process.

Advantages & Disadvantages of Different Types of Laser Cut Wood Sheets

Baltic Birch Plywood

baltic birch plywood Baltic birch plywood is a type of wood sheet that can be laser cut with precision and accuracy. It is a versatile sheet of wood that is strong, durable, and has a unique grain that can be used to create intricate shapes and designs. It is commonly used for furniture, cabinets, displays, and other projects that require accuracy.

Advantages of laser cutting baltic birch plywood include its easy customization through a computer-aided design (CAD) program. This makes it easy to create intricate shapes and designs quickly and accurately.

MDF

wood sheets MDF, or medium-density fiberboard, is one of the most commonly used materials for laser cut wood sheets. It is created by adhering wood fibers, which are very fine particles of wood, with a form of synthetic resin or glue in a hot press process. The result is a highly durable material that is ideal for use with laser cutting machines.

MDF sheets can be bought in a variety of thicknesses and sizes, ranging from thin pieces to very thick ones.

Acrylic

wood Acrylic laser cut wood sheets are an incredibly versatile material used in a range of different craft, prototyping, and decorative projects. Acrylic is relatively easy to cut and can be formed into durable components. Its light weight, high strength-to-weight ratio, and excellent optical properties make it an ideal choice for laser cutting in craft applications.

It is commonly used for laser cutting puzzle designs, 3D models, and intricate wall art. Advantages of Acrylic Laser Cut Wood Sheets * Highly durable and resistant to cracking and chipping. * Lightweight and easy to work with.

Hardwood

Hardwood is a type of wood that is derived from deciduous trees, such as oak, ash, and cherry. Hardwood is a great option for laser cutting because it is dense, hard, and durable. The laser beam is easily able to engrave and cut intricate details into these types of materials.

When laser cutting hardwood, the best results can be achieved when a medium to thick sheet of hardwood is used. The advantages of laser cutting hardwood are that the laser beam is able to precisely cut intricate patterns into the material. This makes it ideal for making custom designs, artwork, and furniture.

Tips For Shopping Laser Cut Wood Sheets

Shopping by Size

4×8 sheets When it comes to shopping for laser cut wood sheets, it’s important to keep size in mind. Laser cut sheets are typically offered in standard sizes such as 4×8′ and 4×10′. These sizes make it easier to precisely plan and layout your project, ensuring it’ll fit perfectly when assembled.

If you’re looking for laser cutting plywood sheets, 4×8′ is the most common size. 4×10′ sheets are more expensive, but they give you the added bonus of extra length if needed.

Shopping by Thickness and Weight

MDF When it comes to laser cut wood sheets, thickness and weight play a big factor in the type of sheet you will end up with. You can use laser cutting to produce a range of different sheet types, each with its own unique characteristics that make it suitable for different uses. When shopping for laser cut plywood sheets, MDF, or other plywood panel options, it’s important to consider the thickness and weight that best suits your needs.

The standard thickness for laser cut plywood sheets is 3-4mm, depending on the type of wood. However, you can find a variety of thicknesses from thinner 1-2mm sheets to thicker 5-8mm options.

Shopping by Grain

wood One of the main types of laser cut wood sheets available is plywood. This type of wood is extremely popular for laser cutting because of its dimensional stability and stability in cutting applications. Plywood is often made from thin sheets of wood that are glued and pressed together using adhesive or fiberglass.

Plywood is typically used for outdoor construction projects because of its strength and rigidity. Another type of laser cut wood sheets is veneer. Veneer consists of wood coated or laminated with another material, such as paper.

Veneer is commonly used for making furniture or creating intricate shapes.

What type of wood is best for laser cutting?

wood When it comes to laser cutting wood, there are a variety of wood materials and grades available for your project. From plywood to hardwood, the material you choose can have a huge impact on the finished product. Knowing which type of wood is best for laser cutting can help you save time, money, and effort in the long run.

For most laser cutting projects, plywood sheets are your best bet. Plywood is inexpensive compared to other wood types, and it’s also easier to work with. Plus, because the layers are so thin, they’re easy to cut with a laser cutter.

Conclusion

Pros and cons of shopping for laser cut wood sheets

MDF The conclusion of exploring the different types of laser cut wood sheets is that it can be a great option for those looking to create a one-of-a-kind piece of art or decoration. Laser cut wood sheets are much easier to handle than traditional woodworking methods and offer a much greater degree of customizability than other wood products. The main pros to laser cutting wood sheets are that you can easily create intricate designs that would be too difficult to make using traditional woodworking methods.

Advantages of using laser cut wood sheets

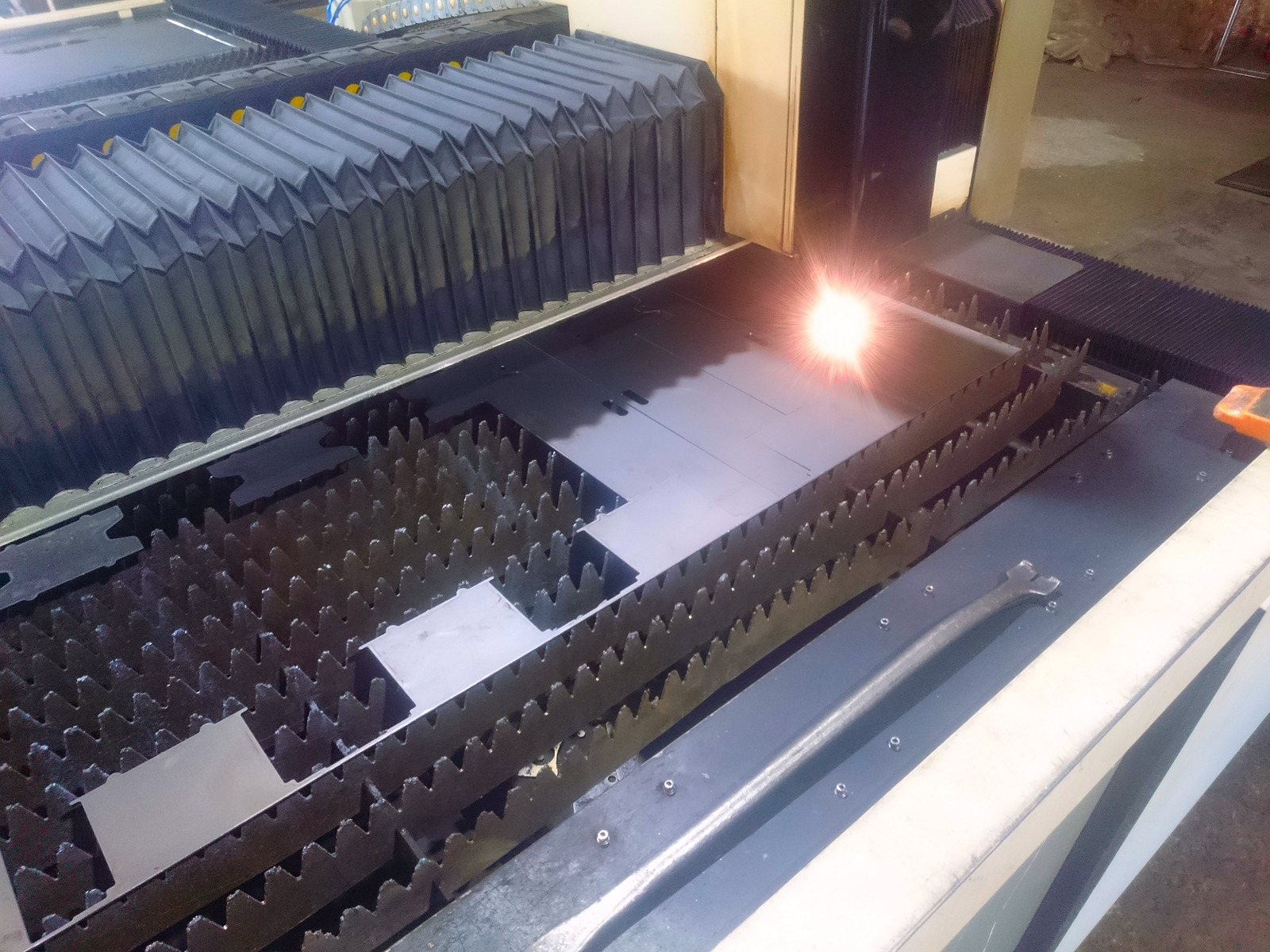

wood Laser cut wood sheets have become increasingly popular in recent years due to their efficiency and precision. They are a great choice for a variety of applications including signage, furniture, toy production, architectural models, cabinet making, and more. There are several advantages to using laser cut wood sheets over traditional methods of cutting wood.

First and foremost, laser cutting is incredibly accurate and precise. A laser beam can do the same cuts over and over again with minimal variation in final shapes. The software and machinery used for laser cutting is also very precise, meaning that you can make complex shapes without worrying about inaccuracies or imprecision in the finished product.