Laser cutting has become an indispensable part of manufacturing, allowing for higher precision and faster throughput. Understanding the financial implications of a laser cutting investment, and how to best position it for a return on investment, can be essential for succeeding in today’s competitive marketplace. This article will discuss the financial benefits of investing in laser cutting technology and help you identify the right approach for your business.

The Pros of Laser Cutting

Automation

A laser cutting investment may be a big undertaking, but the benefits of automation are significant. Automation refers to the use of machines that can be programmed to take a task and repeat it consistently without manual input from operators. When it comes to laser cutting, automation can make large production runs much faster and more efficient, reducing the amount of time it takes to bring a product from idea to market and therefore saving a lot of money and time in the long run.

By investing in a laser cutting machine, you can automate the cutting process for a wide range of materials, including metal, glass, and plastic.

Accuracy

When considering the value of a laser cutting investment, accuracy is a primary capital investment. Be sure the design calls for laser cutting, and that the material is compatible with your needs and abilities. Laser cutting offers superior precision, when compared with conventional fabrication methods, so what is really needed is a laser cutting machine that operates reliably and efficiently.

You avoid the high capital investment needed for purchasing a machine, and can reap the rewards of a profitability laser investment. Cost Per Cut is one of the key metrics to consider when evaluating the value of a laser cutting investment.

Cost-effectiveness

Understanding the Value of a Laser Cutting Investment, The Pros of Laser Cutting: Cost-effectiveness One of the main benefits of a laser cutting investment is the cost-effectiveness. It is important to be sure that the design calls for laser cutting and the quantity is large enough to offset the cost associated with the initial capital investment. With laser cutting, what you avoid is the high capital investment needed for purchasing a machine, which is a much more cost-effective solution.

When evaluating the cost-effectiveness of a laser cutting investment, it is important to measure by “Cost Per Cut”.

The Cons of Laser Cutting

Maintenance requirements

When it comes to understanding the value of a laser cutting investment, one of the major cons is the maintenance requirements and the cost related to it. While the benefits of laser cutting can be great, it comes with a hefty price tag as well. Be sure the design calls for laser cutting before making the investment.

Maintenance is one of the biggest costs associated with a laser cutting investment. This can include regular maintenance checks and repairs, and in some cases replacement parts.

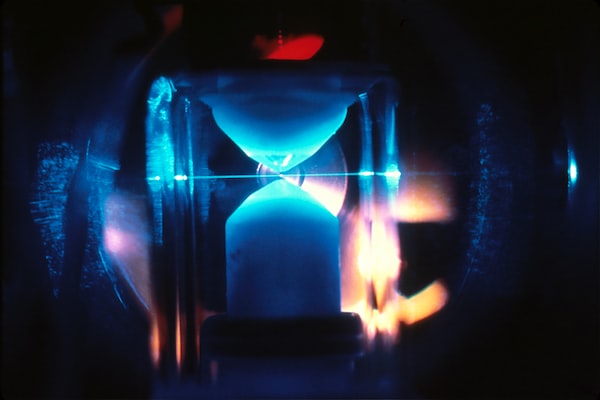

Heat-affected zone

When considering the value of a laser cutting investment, a key factor to consider is the heat-affected zone (HAZ). The HAZ is a region of metal around a cut formed as a result of the high temperatures encountered during cutting. The degree of distortion and hardness change as a result of the elevated temperature ranges during the cut, and cutting too much material at once can cause an oversized HAZ.

Be sure the design calls for laser cutting before making an investment and be prepared for material movement when cutting complex pieces. When considering a laser cutting investment, it’s important to consider not only the initial capital investment for purchasing a machine, but also the cost per cut.

What Types of Materials can be Laser Cut?

Metals

When it comes to understanding the value of a laser cutting investment, one must consider what types of materials can be laser cut. When dealing with metals, a laser cutting machine can be highly advantageous. Whether you opt for a CO2 laser, or a more recent fibre laser, you can be sure the design calls for laser cutting.

Laser cutting is a highly precise machining process, and what is more, this precision comes with a high degree of repeatability. This kind of accuracy is ideal for industrial applications, as it can save time, reduce waste and increase work production on the whole.

Plastics

Investing in laser cutting technology is a great way to unlock the potential of your business and get ahead of the competition. Plastics are among the materials that can be cut with lasers, but there are a few things to keep in mind when planning out a project. First, be sure that the desired design for the project calls for laser cutting.

Laser cutting is a great way to produce complex shapes with precision and accuracy, but there are some applications where traditional cutting methods may be more effective.

Cardboard

Cardboard is an excellent material for laser cutting because of its thinness, versatility, and affordability. Many businesses, from automotive to apparel, use laser cutting machines to shape their cardboard materials. Laser cutting machines can cut cardboard into intricate designs and shapes, making it a great way to ensure precision and accuracy.

The benefits of laser cutting are far-reaching. Laser-cut cardboard pieces are strong and durable, making them ideal for a wide range of uses.

Determining The Cost of Investing in Laser Cutting

Initial investment

When you’re considering making an investment in laser cutting technology, it’s important to do your research and understand the value of the initial investment. Ultimately, you want to pick the size and type of laser that best fits your goals for cutting. To determine the cost of investing in laser cutting, it’s important to consider what your ideal design calls for.

Laser cutting is especially advantageous when processing materials with small cutting thicknesses and materials that require a small kerf.

Maintenance and operating costs

Maintenance and operating costs are key considerations when determining the value of a laser cutting investment. Knowing the costs to run and maintain a laser cutting machine helps you to better identify usage patterns and maximize return on investment. One of the main reasons to invest in a laser cutter is the low capital investment needed to purchase a machine.

However, there are other costs associated with the machine that should be taken into account when calculating the return on investment. First, determine the type of laser you need. For example, an 8-kilowatt laser or a 10-kilowatt fiber laser may be the optimal solution for job shops seeking to maximize throughput and minimize cost per cut.

Required space

When it comes to understanding the value of a laser cutting investment, one key element to consider is the requirement for physical space. In order to accommodate the machine, some losses due to inefficient layouts can occur, making it necessary to plan ahead and be sure that the design calls for laser cutting and other materials for a correctly scaled, efficient shop. The good news is that you avoid the high capital investment needed for purchasing a laser cutting machine because there are rental services that provide a variety of options.

Manufacturing facilities may rent or lease the necessary equipment as needed, as well as a complete set of services, software and hardware, to take full advantage of that investment.

Conclusion

Benefits of laser cutting

Understanding the Value of a Laser Cutting Investment, Conclusion: Benefits of laser cutting When considering any size of purchase, it is important to understand what the investment will be and what benefits you will get in return. When investing in a laser cutting machine, there are four key areas to consider: a primary capital investment, the cost per cut, the ability to produce a variety of components in a short time-frame and the ability to produce high-quality components to exacting standards.

Considerations when investing in laser cutting

When considering the value of a laser cutting investment there are several key factors to consider. Be sure the design calls for laser cutting, as it’s not the best fit for every job. It’s important to consider what is the anticipated work volume and the complexity of parts you will be fabricating.

You want to make sure you avoid the high capital investment needed for purchasing a machine. The cost per cut will be a primary factor to consider when investing in laser cutting.