As businesses become increasingly competitive and customer expectations rise, the ability to maintain productivity and efficiency has become a priority. To meet these demands, companies are turning to new laser cutting designs to boost productivity and create greater value. This article will look at how laser cutting technology can help to increase productivity, how it has been leveraged effectively, the advantages and disadvantages of the technology, and the considerations to make when using it.

What Is Laser Cutting?

Overview of laser cutting principles

Laser cutting is a precision manufacturing technique that uses a highly intense laser beam to cut through materials. The laser is directed through a computer numerical control (CNC) system, which instructs the laser to cut and shape the material into the desired design. Laser cutting is often used for intricate and detailed designs, as well as complex three-dimensional shapes.

The laser cutting process involves a focused beam of light which is passed over the material.

Popular materials suitable for laser cutting

Laser cutting is a popular and effective process used to cut through many types of materials. The process relies on a powerful beam of light, usually produced by a CO2 laser, that is directed at a material and focused to quickly and precisely melt, burn or vaporize it. In terms of materials, laser cutting offers a wide range of options – both industrial and hobbyist materials are suitable for laser cutting.

The Latest Laser Cutting Designs

Overview of new designs

The latest in laser cutting designs are revolutionizing the way that products are being created. With the use of lasers to cut highly complex materials, manufacturers are able to produce high-quality parts with incredible precision. This process offers the potential to create parts with exceptional quality and speed, while using less material.

The latest laser cutting designs focus on using optimized cutting paths and processes to increase the productivity of the process. For example, the use of multiple passes and optimized cutting trajectories allows for more parts to be made in a shorter period of time.

Application of new designs to increase productivity

The world of laser cutting is constantly evolving, and new designs are proving to be an efficient way to boost productivity. There are many different types of laser cutters on the market, with each offering unique capabilities and benefits. While conventional laser cutting techniques are still being used in some industries, new designs are emerging to provide more efficient and cost-effective solutions.

In industries where the speed of production is paramount, the use of high-precision laser cutting technology is becoming more common.

Advantages and Disadvantages of Laser Cutting

Pros of laser cutting

The pros of laser cutting are numerous and can result in a significant increase in productivity for any business with cutting needs. One of the main advantages of laser cutting is the accuracy of cuts that can be achieved, which can greatly reduce production time and waste. Laser cutters can cut through a huge range of materials, from plastics and paper through to metal and many other alloys.

Laser cutters can also be used to create very intricate designs, as the laser beam can be programmed with a number of different power settings, and using multiple passes the cutter is able to create very intricate and precise designs.

Cons of laser cutting

A major con of laser cutting is the cost. It’s an expensive technology and the initial costs can be quite high. Plus, the materials used must be specially able to withstand the high temperatures that the laser produces.

This can limit the types of materials that you can use with laser cutting, and of course, makes the technology more costly. Another con is that laser cutting can suffer from low accuracy when thicker materials are being cut.

Strategies For Improving Productivity

Optimizing cutting speed and process for efficiency

Optimizing cutting speed and process is key to improving the efficiency of laser cutting designs. To get the most out of the laser cutting process, it is important to understand the cutting parameters of the laser and explore the variety of approaches available to increase productivity. The first step in optimizing cutting speed and process is to identify common materials and shapes.

It’s important to get a good understanding of the desired materials, their tolerances and the exact sizes of finished parts. This will help you determine the optimum cutting speed, which should be near the rated speed of the laser. Additionally, you should optimize the cutting path for each shape and material for maximum speed.

Utilizing cutting paths for accuracy

When it comes to increasing productivity with new laser cutting designs, one of the most important factors is accuracy. Utilizing cutting paths correctly can play a major role in ensuring that projects are completed quickly and correctly. A cutting path is a programming tool that defines the directions, speed, and other parameters when directing a laser cutter to cut a given project.

When it comes to programming a laser cutter, understanding the basics of cutting paths is key. Cutting paths can be used to direct the machine’s movements in both the X and Y-axes, as well as the depth of cut.

Identifying potential areas of improvement

Identifying potential areas of improvement to your laser cutting process can be daunting, but it is essential for improving productivity. The first step is to get an idea of your current process. Study the flow of your laser cutting process, from order entry to finished product, and identify any steps that cause inefficiencies or lengthy delays.

You can also consider if there are any processes that can be improved with the addition of new tools or technology. Once you have an idea of your current process, it’s time to brainstorm new ideas.

What is the future of laser cutting?

The future of laser cutting is incredibly bright. As technology continues to develop, more innovative laser cutting designs are becoming available, making it easier than ever for companies to innovate and increase their productivity. With the increasing number of materials that can be cut with lasers, more industrial applications are possible.

New laser cutting design options are offering opportunities for a variety of industries to improve their efficiency. These new designs offer faster speeds, higher cutting accuracy and improved safety.

How is laser cutting used in the design industry?

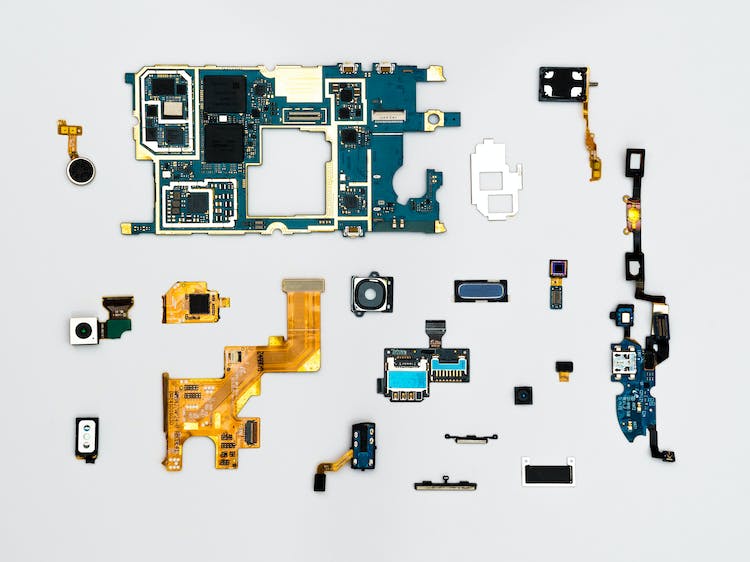

Laser cutting is a type of technology commonly used in the design and manufacturing industry to cut and etch complex shapes and designs into a variety of materials. It is typically used for rapid prototyping and the creation of one-off and short-run production projects. Laser cutting is quite a versatile manufacturing process, as it can be used for many different materials such as acrylic, plastic, wood, and even metal.

The laser cutting process works by using an industrial machine, containing a high-powered laser, to precisely and accurately cut and etch intricate shapes into a material. The precision of the laser allows shapes to be cut to almost any specifications needed.

Conclusion

Summary of the key points

In this blog post, we have discussed how the new laser cutting designs can help to significantly increase productivity in many industries. Firstly, the new laser designs have allowed for more precise, efficient cutting of shapes and materials, saving time and material waste. Secondly, new software and robotics have enabled faster, more consistent production.

Thirdly, advanced sensors and AI technologies allow for real-time monitoring, making it easier to identify and fix any issues quickly.

Benefits of leveraging new laser cutting designs to increase productivity

The conclusion of how to leverage new laser cutting designs to increase productivity is that it can provide a great advantage to businesses. By investing in the right technology and training, businesses can enjoy the benefits of improved accuracy, efficiency, flexibility, and cost savings. This can lead to improved end product quality and a competitive edge.

- Stay informed on the latest trends, technology, and materials to make sure you are always up to date with the available laser cutting designs.

- Utilize specialist programs that can calculate laser cutting design options to help you optimize results.

- Introduce automation into your modelling and production process to increase productivity and accuracy.

- Invest in CNC machines to make quicker and more precise cuts if dealing with complex models.

- Identify parts and components that can be mass-produced in one go to reduce production time.