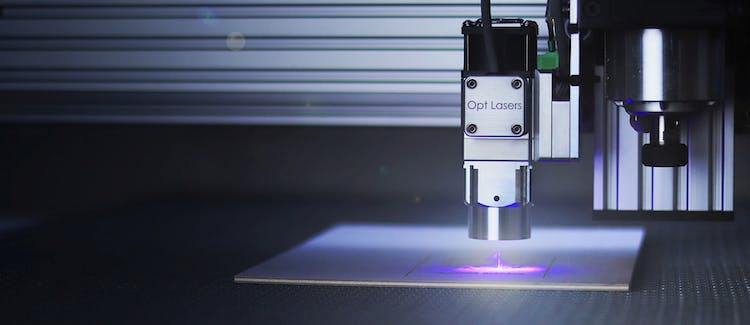

Laser cutting machines have become a game changer in today’s industrial sectors due to their ability to quickly and accurately cut, engrave, and finish a wide range of materials. This technology has revolutionized the manufacturing world, and it is now being utilized in a variety of industries for all sorts of applications. In this article, we will take a closer look at the various applications of laser cutting machines in industrial sectors and how they are bringing improved accuracy, efficiency, and speed to various processes.

Types of Laser Cutting Machines

CO2

CO2 laser cutting is one of the most popular types of laser cutting machines used in industrial sectors. It is frequently used in many manufacturing applications, including the production of automotive and aerospace components, electronics and medical products, and for industrial laser cutting and welding operations. It is well-suited for creating intricate shapes and details in workpieces of varying materials, even those that are thicker than other materials.

This type of laser machine uses CO2 gas, which is activated by an electric pulse, to produce an intense beam of light that is focused onto the material to be cut.

Fiber

One of the most popular types of laser cutting machine used in industrial sectors today is the fiber laser cutting machine. This type of machine uses a beam of laser light generated by a high-energy source, such as a CO2 gas laser, to produce a powerful cutting action. This beam of laser light is then focused onto a specific material, such as steel, aluminum, copper, or other metals, with a reflector that amplifies the laser beam and directs it to the material.

Nd:YAG

Nd:YAG (Neodymium-Doped Yttrium Aluminum Garnet) is one of the most commonly used lasers for industrial applications. It is a solid-state laser that uses carefully doped crystals to produce a beam of high energy, wavelength-specific light. This type of laser is powerful and commonly used for applications like cutting, engraving, and marking.

Advantages of Laser Cutting Machines

Speed

When it comes to laser cutting machines, one of the major advantages to these devices is their incredible speed. Laser cutters can quickly and accurately cut through a variety of materials, making them ideal for industrial applications. Compared to traditional cutting machines, laser machines can operate at a faster speed and with more precision.

This means that projects can be completed faster, giving them an edge over traditional methods. Furthermore, laser cutters are capable of cutting through multiple materials at the same time, allowing for faster production lines.

Accuracy

One of the most impressive advantages of laser cutting machines is the remarkable accuracy they offer compared to other methods of cutting materials. By using a focused beam of light, these machines are able to cut with greater precision than more traditional cutting machines. In some scenarios, laser cutting machines can be accurate to within 0.01mm, which is an incredible level of detail for any kind of industrial cutting.

This accuracy can be over both small and large areas, which makes it ideal for creating precise shapes and intricate designs.

Cost-efficiency

One of the main advantages of using laser cutting machines in industrial sectors is their cost-efficiency. The cost of operating a laser cutting machine for large-scale production is much lower than conventional construction methods thanks to their high precision and accuracy. Laser cutters are able to produce components with greater precision without having to make any additional effort, which results in cost savings.

Plus, laser cutting systems can be used to cut into many different materials, making them a versatile option when it comes to industrial production.

Applications of Laser Cutting Machines in Industrial Sectors

Aerospace

A laser cutting machine is an industrial tool used to cut through a variety of materials in the aerospace industry. It uses a focused beam of light to create precise cuts and shapes. Laser cutters have become increasingly popular in the aerospace sector due to the precision and accuracy that laser-cutting provides.

Laser cutters have a variety of applications throughout the entire industrial sector, with aerospace being no exception.

Automotive

The use of laser cutting machines in the automotive industry has become increasingly common in recent years. Laser cutting has become a popular tool for several reasons: it’s fast and accurate, has minimal material loss due to its precision cutting, and is more efficient than mechanical methods. Laser cutting systems can be used for a range of automotive parts, from simple components such as identification plates to complex, high-precision parts such as steering wheels and windshields.

Medical

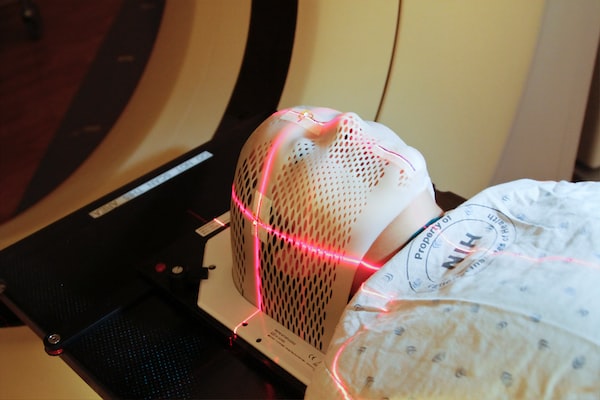

Laser cutting machines have become increasingly popular in the industrial sector due to their immense capabilities. In the medical industry, laser cutting machines and laser engravers are used for a variety of applications. From operations to diagnosis and fabrication, laser cutters are an invaluable tool.

Laser cutters are used to create precision devices, such as artificial limbs and implants.

Textiles

Laser cutting machines are an essential tool used in many industrial sectors, including the textile industry. Laser cutting machines can be used to accurately cut, engrave, and mark textiles made of fabric, plastic, leather and more. They enable a precise and efficient cutting experience that is unlike any other traditional cutting methods.

In the textile industry, laser cutters are used to cut intricate and precise designs into fabrics and other materials, providing the necessary accuracy and speed to the production process. The precise nature of the cuts made by laser cutting machines also enables better patterns for fabrics and other materials that can be difficult to achieve by hand.

Jewelry

When it comes to the application of laser cutting machines in the jewelry industry, the possibilities of what can be done are truly endless. One of the most common uses of laser cutting machines in the jewelry industry is laser engraving. With this process, fine details can be laser-engraved onto both soft and hard materials, creating unique and intricate designs.

Engraving is a very popular step in the jewelry creation process, as it allows manufacturers to add branding, logos, unique shapes, or even personalized messages to each piece of jewelry. Another great application of laser cutting machines in the jewelry industry is the cutting of different types of metal or even glass.

Safety Considerations

Hazards

When it comes to using laser cutting machines in industrial settings, safety is of the utmost importance. Laser cutting systems create intense light beams set at predetermined power settings that can penetrate a variety of materials. As such, the effects of laser cutting machines can be hazardous to both operators and other workers in their vicinity.

Protective equipment

When it comes to using laser cutting machines in industrial sectors, safety precautions must be taken to ensure the safety of both the worker and the machine. One such safety measure is to use protective equipment. Protective gear for laser cutting applications includes safety glasses, gloves, face shields, and other relevant items, such as respirators and pit masks.

Safety glasses should be worn specifically to protect against intense laser radiation, as laser radiation can damage a person’s eyesight and even cause severe burns. Face shields should be worn if there is a danger of small pieces of metal being thrown around, as they provide an extra layer of protection.

Conclusion

Summary

In conclusion, laser cutting machines offer a wide range of industrial applications that have both practical and creative uses. The main benefits of laser cutting machines are its speed, accuracy and flexibility. These machines have opened up many new avenues for manufacturing and production, allowing for faster and more precise production than ever before.

Laser cutting machines also have many creative applications as they can be used to create intricate designs and patterns.

Outlook

The outlook for laser cutting machine applications in the industrial sector is promising. In the future, we can expect uses of laser cutting to become more diversified and efficient, while the technology advances to process materials faster, with higher precision and accuracy, improved safety and consistency. Further, the introduction of multi-axis laser cutting machines with multiple lasers, will create potential for greater output, allowing for competitive pricing and greater production.

With these significant gains, laser cutting machines are set to be more dominant in the industrial sector in years to come.