The manufacturing industry is rapidly changing, with advancements in technology allowing for increased efficiency, accuracy, and cost-effectiveness. Among the leading technologies to revolutionize the industry are 3D printing and laser cutting. These two powerful processes provide the potential to open up new manufacturing horizons to everyone, from the smallest independent shop to the largest factory complex. With their capability to precisely produce complex shapes in a fraction of the time of traditional methods, 3D printing and laser cutting are setting the trend for the future of manufacturing.

3D Printing

Advantages of 3D Printing

3D printing is the process of creating three dimensional objects from a digital file. 3D printing has been increasing in popularity since the early 1990s. One of the advantages of 3D printing is the ability to produce items quickly and with a high degree of accuracy.

It also allows for the design and print of more complex designs than traditional manufacturing processes. This is due to the fact that 3D printing involves the melting of materials, such as plastics and metals, together layer by layer to eventually form an object. 3D printing has a very wide range of potential materials, allowing for the production of items with different properties and characteristics.

Disadvantages of 3D Printing

methods Though 3D printing has the potential to revolutionize the manufacturing process, it does have a few drawbacks. Namely, the range of materials that can be used in the 3D printing process is still rather limited. 3D printing is an additive manufacturing method, meaning material is added layer by layer to create an object.

This greatly restricts the types of materials that can be used. Additionally, traditional manufacturing processes, such as laser cutting and milling, can produce more intricate designs than 3D printing. Though the 3D printing market is growing rapidly, it only amounted to $15.2 billion in 2021, a growth of 19.5 percent.

Examples of 3D Printing

tools 3D printing is an incredible process that allows us to create intricate and complex designs from a variety of materials. Traditionally, manufacturing processes rely on cutting away or creating a shape from a block of material, but 3D printing is a type of additive manufacturing, meaning that instead of cutting away material, the printer builds up the material layer-by-layer to create the desired design. This creates a wide range of potential materials and allows for the design and printing of more complex designs than traditional manufacturing processes.

3D printing has seen tremendous growth in recent years due to its versatility and efficiency.

Laser Cutting

Advantages of Laser Cutting

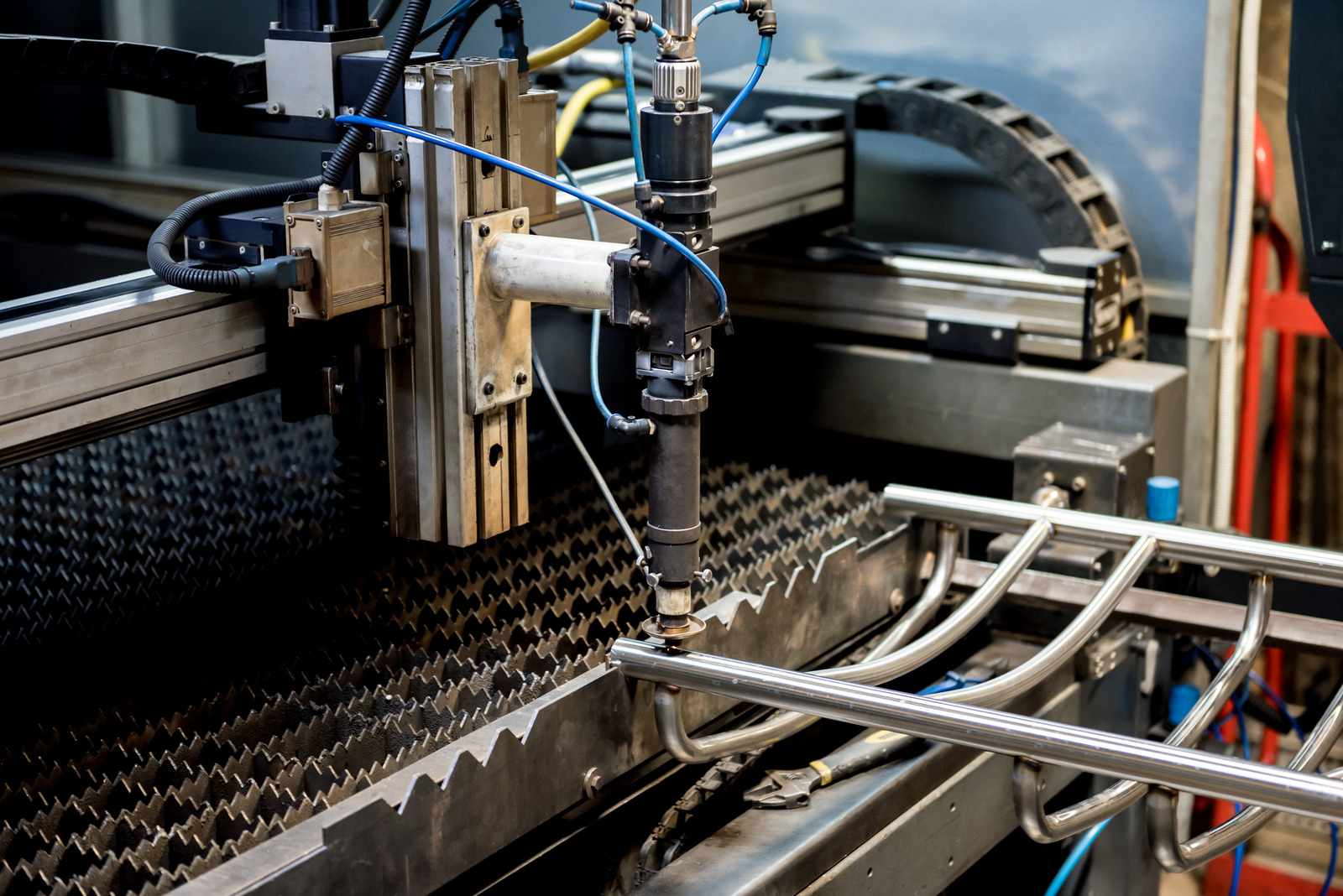

The advantages of laser cutting are becoming increasingly apparent to manufacturing and production companies. Laser cutting is an incredibly precise form of cutting metal and other materials that is a major step up from traditional methods. It is immensely accurate, with a tolerance range of as little as .01mm, providing highly precise cuts that are almost always perfect.

In addition, the speed and accuracy of laser cutting makes it far superior to other types of manufacturing processes. For example, with 3D printing, you are limited to the range of materials available for printing, such as plastics and metals.

Disadvantages of Laser Cutting

The future of manufacturing has been impacted in a huge way by the growth of 3D printing and laser cutting. These technologies have revolutionized production processes and made the creation of complex designs much easier and more cost effective. 3D printing has a very wide range of potential materials that are able to be printed and its growth in 2021 was impressive, increasing by 19.5 percent to a total of $15.2 billion.

Laser cutting has also proved to be immensely helpful, as it allows for greater precision and faster production than ever before.

Examples of Laser Cutting

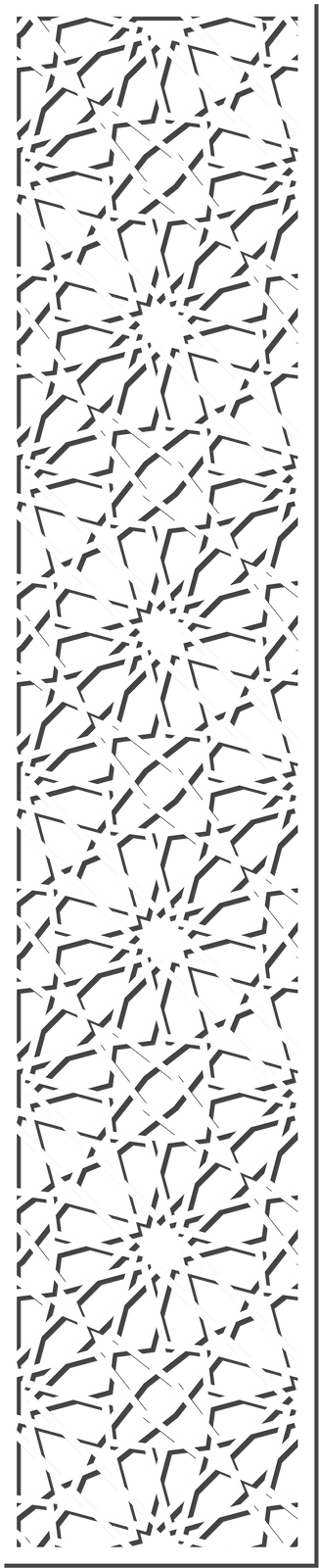

Laser cutting is a technology that is rapidly gaining traction among manufacturers and designers in the world of 3D printing. This process uses a powerful laser beam to cut intricate shapes and patterns into any type of material. This type of cutting is extremely precise as it enables designers to make intricate cuts with accuracy that is not achievable through manual techniques.

It can be used in a wide range of applications, such as jewelry and automotive work, as well as the production of medical and industrial equipment. Unlike 3D printing technology, laser cutting does not require the use of specialized software and is instead implemented through a manually operated computer-controlled machine.

Future of Manufacturing

Impact of 3D Printing and Laser Cutting on the Manufacturing Industry

The impact of 3D printing and laser cutting on the manufacturing industry is undeniable. 3D printing has revolutionized the way products are produced, as 3D printers have made it possible to create complex designs from simple input data. 3D printing can also be used on a wide range of materials, which means manufacturers now have the ability to create products more quickly and efficiently than ever before.

Potential Benefits of Adopting 3D Printing and Laser Cutting Technology

technology With the recent rise of 3D printing and Laser Cutting technology, there is no denying that this is the future of manufacturing. The potential benefits of these technologies have a wide range of potential applications across many different industries. 3D Printing provides businesses with the ability to design and create complex designs and components, which allows them to save costs, increase productivity, and even make customization possible.

The technology is becoming increasingly more affordable and accessible for businesses of all sizes and has seen remarkable growth in recent years with the global 3D printing market size growing by 19.5 percent in 2021 to $15.

Challenges with Implementing 3D Printing and Laser Cutting Technology

The emergence of 3D printing and laser cutting technologies offer a wide range of potential applications in product manufacturing, industrial design and rapid prototyping. This new approach to manufacturing is not without its challenges however. Many businesses are having to rethink their production flow and the operational costs of 3D printing and laser cutting technologies, which can present unique and complex challenges.

Is there a future in 3D printing?

The future of manufacturing is in 3D printing and laser cutting. With 3D printers, the ability to cut and shape materials is revolutionized, allowing for the design and fabrication of more complex parts and products than traditional manufacturing processes. This is known as additive manufacturing and it has seen incredible growth in the last year, with spending rising by 19.5 percent in 2021 to $15.2 billion.

The ability to use 3D printers and laser cutters in the production of products is one of the most cutting-edge advancements in manufacturing.

Is 3D printing the future of sustainable manufacturing?

Is 3D printing the future of sustainable manufacturing? There’s no doubt that this technology is making a huge impact on the manufacturing industry. 3D printing (also known as additive manufacturing) allows for the design and printing of more complex designs than traditional manufacturing processes.

Over the years, 3D printing technology has grown rapidly, with some estimates suggesting that the total 3D printing market grew by 19.5 percent in 2021 to $15.2 billion.

What is the future of 3D printing in manufacturing?

As the demand for faster and better-quality products grows, 3D printing and laser cutting technology has become an increasingly popular tool for manufacturers looking to stay ahead of the competition. These two technologies have allowed for the design and print of more complex designs than traditional manufacturing processes, and 3D printing has a very wide range of potential materials. The 3D printing industry in the United States alone has grown by 19.5 percent in 2021 to $15.2 billion, according to market estimates.

With such impressive figures, it’s no wonder that more and more companies are looking to capitalize on the potential of 3D printing to produce their parts in a more timely and cost-effective manner.

Will 3D printing replace manufacturing?

The short answer to the question of whether 3D printing will replace traditional manufacturing is ‘not yet.’ 3D printing, also known as additive manufacturing, offers a great range of potential materials, and the ability to design and print more complex designs than traditional manufacturing methods, making it an attractive option in many areas. However, 3D printing is still a relatively new technology and traditional manufacturing processes remain more cost-effective, accurate, and robust for many applications.

Conclusion

Summary of 3D Printing and Laser Cutting in Manufacturing

In conclusion, 3D printing and laser cutting technologies have immense potential for reshaping the future of manufacturing. 3D printing is a rapidly growing industry, having grown by 19.5 percent in 2021 to $15.2 billion. It has a very wide range of potential materials and allows for the design and print of more complex designs than traditional manufacturing processes.

Additionally, laser cutting gives manufacturers a great deal of flexibility when working with metal surfaces. With the right machine, teams can quickly and accurately cut metal with minimal human effort. Magod Laser recently used the concept to double our workshop space with just one machine.

Benefits of Adopting New Manufacturing Technologies

Adopting new manufacturing technologies such as 3D printing and laser cutting offers numerous benefits for businesses. 3D printing allows for the design and production of more complex items than traditional manufacturing processes. In addition, 3D printing has a very wide range of potential materials that can be used in production.

This opens up opportunities for companies to create unique, custom pieces that weren’t possible before.